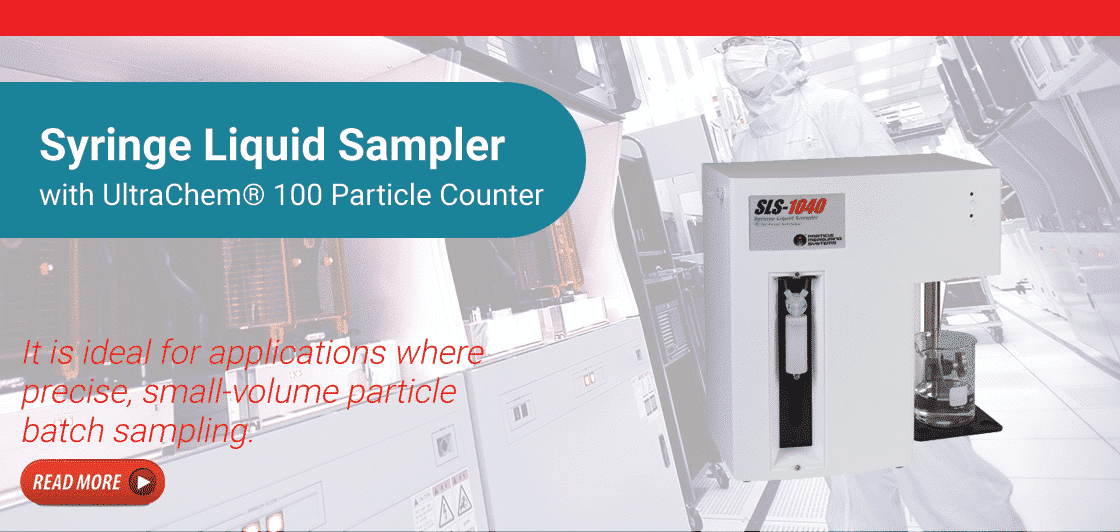

Introduction Syringe Liquid Particle Sampler PMS SLS 1100

The PMS SLS 1100 Syringe Sampling System is ideal for applications where precise, small-volume sampling is needed.

The system consists of a syringe sampler for either corrosive or non-corrosive liquids, a particle counter for different sizing sensitivities, and software.

A convenient naming system identifies the particle counter installed inside the instrument (see the Specifications table).

Features Syringe Liquid Particle Sampler SLS 1100

- Proven PMS UltraChem particle sensors

- Menu-driven data collection – 1, 5, 10 and 25 ml

- Wetted materials compatible with corrosive chemicals

- Compact design with on-board particle sensor

Benefits Syringe Liquid Particle Sampler SLS 1100

- Precise particle measurement

- Versatile – select various particle sensors and syringe sizes

- Cost-effective

- Easy-to-use

- Small sample volume – eliminates sample waste

Specifications

| Syringe size | 25 ml |

| Sampling mode | Vacuum, Batch |

| Minimum sample size | 0.4 ml, 20 ml/min |

| Wetted surface materials | Glass, Teflon® (all Teflon optional) |

| Power | 100 – 240 V, 50 – 60Hz |

| Sample volume | Adjustable using software interface |

| Dimensions (l, w, h) | 38.1 x 22.0 x 43.4 cm, including particle counter |

| Weight | 19.1 kg including particle counter |

| Environment Temperature | 10 – 30 ºC, |

| Humidity | Non-condensing |

| Particle Sensor | UltraChem 100 |

| Particle Size range | 100 – 500 nm |

| Channels | 100, 200, 300, 500 nm |

| Flow rate | 20 ml/min |

| Sampled % | 30% Monitor mode; 16% Spectrometer mode, 13% High-Scatter mode |

| Maximum concentration | 3000 particles/ml Monitor mode, 9000 particles/ml Spectrometer mode, 15000 particles /ml, High-Scatter mode |

| Zero count | < 50 counts/l |

| Sample temperature | 50 – 122 °F (10 – 50 ºC) |

| Calibration | Materials used are traceable to US National Institute of Standards and Technology (NIST) and Japanese Institute of Standards (JIS). |

| Software | SamplerSight |

Applications

- Diverse applications in semiconductor and process chemical manufacturing

- Incoming quality measurement of process chemicals

- Point-of-process monitoring on process tools

- Testing and qualification of chemical components

- Outgoing chemical qualification testing

- Mechanical parts cleanliness testing

Reviews

There are no reviews yet.