Sensitivity: 10 nm, Flowrate: 2.8 LPM (0.1 CFM)

Purpose-built nanoparticle counter designed specifically for use in the most critical fab spaces.

The NanoAir™ 10 Condensation Particle Counter (CPC) is a revolutionary new product from Particle Measuring Systems (PMS). It provides the sensitivity of a CPC with the ease of use and functionality of a traditional cleanroom particle counter. Designed to monitor ultra-clean environments, it delivers 10 nm detection sensitivity at a sample flow rate of 2.8 L/min (0.1 CFM).

The NanoAir 10’s size is 83% smaller than competitive products making it practical to use anywhere in ultra-clean environments, including inside semiconductor process tools and equipment front-end modules (EFEM). The innovative patent-pending working fluid handling system design is robust and efficient, enabling 24/7, 365 days continuous operation without the need for maintenance or user intervention of any kind between the annually required working fluid refill and calibration. Thereby, reducing sampling and data collection interruptions and tool downtime.

A 10-port manifold companion product (ParticleSeeker™) supports applications that require multiple sample locations to be monitored in sequential or programmed sequences.

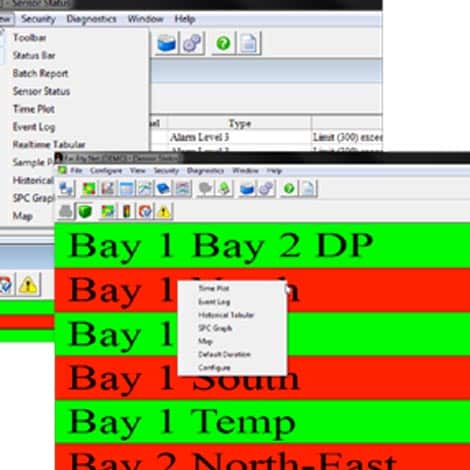

Additionally, the NanoAir is high-pressure gas compatible with the HPD-III from PMS, and data can be viewed, analyzed, and reported using PMS Facility Net facility monitoring software or transmitted directly to third-party SCADA systems or process tool inputs.

Product Details

The NanoAir™ 10 Condensation Particle Counter (CPC) is a revolutionary new product from Particle Measuring Systems (PMS). It provides the sensitivity of a CPC with the ease of use and functionality of a traditional cleanroom particle counter. Designed to monitor ultra-clean environments, it delivers 10 nm detection sensitivity at a sample flow rate of 2.8 L/min (0.1 CFM). The NanoAir 10’s size is 83% smaller than competitive products making it practical to use anywhere in ultra-clean environments, including inside semiconductor process tools and equipment front-end modules (EFEM). The innovative patent-pending working fluid handling system design is robust and efficient, enabling 24/7, 365 days continuous operation without the need for maintenance or user intervention of any kind between the annually required working fluid refill and calibration. Thereby, reducing sampling and data collection interruptions and tool downtime. A 10-port manifold companion product (ParticleSeeker™) supports applications that require multiple sample locations to be monitored in sequential or programmed sequences. Additionally, the NanoAir is high-pressure gas compatible with the HPD-III from PMS, and data can be viewed, analyzed, and reported using PMS Facility Net facility monitoring software or transmitted directly to third-party SCADA systems or process tool inputs.

Resources

Educational Materials

- Selecting an Airborne Particle Counter

- Airborne Molecular Contamination Monitoring Optimized for Lithography

- Real-Time Monitors: Review and Lithography Applications

- AMC Airborne Molecular Contamination Control in Clean Manufacturing Environments

Accessories

ParticleSeeker™ Multiport Aerosol Sampler >

High-Pressure Diffuser >

Facility Net >

Not sure where to start? Here are the next steps:

Tell us about your application requirements.

Our experts will help you find the right solutions to meet your specific requirements.

Once we identify the best solution for you, we provide you with pricing and delivery dates.