SPECIFICATIONS TECHNICAL ARC OPTeCUT WHD EXTREME PERFORMANCE PLASMA 200A-300A WATER COOLED

+ OPTeCUT 200WHD

| Specifications | OPTeCUT 200WHD |

| Amperage range | 25-200A |

| Duty cycle 60%

Duty cycle 100% |

200A

160A |

| Maximum no load volts (OCV) | 340V |

| Input fuse size (D) (400V 3 phase) | T45/63A |

| Maximum output power 60% duty cycle | 34kw |

| Server cut capacity – manual cutting (Mild steel) | 77mm |

| Server cut capacity OPTeBOOST – manual cutting (Mild steel) | 83mm |

| Recommended max production cut, (Mild steel) | 50mm |

| Maximum pierce thickness | 32mm |

| Max cut speed at maximum output 10mm mild steel | 3800mm/min |

| Max cut speed at maximum output 20mm mild steel | 1700mm/min |

| Max cut speed at maximum output 30mm mild steel | 1100mm/min |

| Max cut speed at maximum output 40mm mild steel | 550mm/min |

| Power source case size approx.

|

530mm W X 900mm L x 1000mm H |

| Power source weight | 260kg |

+ OPTeCUT 300WHD

| Specifications | OPTeCUT 300WHD |

| Amperage range | 25-300A |

| Output power at 60%

Output power at 100% |

300A

250A |

| Maximum no load volts (OCV) | 350V |

| Input fuse size (D) (400V 3 phase) | T63/80A |

| Maximum output power 60% duty cycle | 53kw |

| Server cut capacity – manual cutting (Mild steel) | 88mm |

| Server cut capacity OPTeBOOST – manual cutting (Mild steel) | 95mm |

| Recommended max production cut, (Mild steel) | 60mm |

| Maximum pierce thickness | 35mm |

| Max cut speed at maximum output 10mm mild steel | 4700mm/min |

| Max cut speed at maximum output 20mm mild steel | 2100mm/min |

| Max cut speed at maximum output 30mm mild steel | 1300mm/min |

| Max cut speed at maximum output 40mm mild steel | 800mm/min |

| Power source case size approx.

|

530mm W X 900mm L x 1000mm H |

| Power source approx weight | 330kg |

Introduction Technical ARC OPTeCUT WHD Extreme performance Plasma 200A-300A water cooled

OPTeCUT WHD range are our heaviest duty plasma cutting machines with outstanding performance!

Technical ARC OPTeCUT WHD Extreme performance Plasma 200A-300A water cooled – Made in UK.

All our OPTeCUT plasma models are built using our renowned OPTeARC hybrid chopper technology. This combines the performance advantages you get from the best inverter with the rugged reliable build of an older type machine. This gives you exceptional cutting performance & the high efficiency means less input power & more output power allowing us to push the boundary of whats normally possible on a given supply.

Standard functions & features

- Instant arc starting using our unique electronic impulse system.

- Built in water cooling system with flow switch protection.

- Built in CNC interface ready to connect to a cutting table or other device.

- Digital ammeter & voltmeter shows true values when cutting.

- OPTeBOOST provides up to 1 min of 25% extra cut power.

- Machine torches & manual hand torches can be changed in seconds.

- Built to work with at least 3 different makes of water cooled plasma torch.

- Works with compressed air or Nitrogen as a plasma gas.

- All machines come with CNC interface fitted standard (with variable divided volts output).

- Will also work with large air cooled hand torches.

Key benefits of OPTeCUT WHD PLASMA models

- Cut all metallic materials with ease, steel, stainless, aluminium, hardox, copper, brass etc.

- Exceptional cut quality from both models with near perfect narrow straight cuts.

- Liquid cooling brings big benefits over air cooled plasma-please see more below.

- Over 90% efficiency means amongst the lowest power consumption in class.

- Superb gouging performance.

- Generator friendly design guarantees no damage even if the generator is unstable!

- Not affected by dirty harsh environments like inverter based machines are.

- Really rugged industrial design for the longest possible life.

Further info.

OPTeCUT 200 + 300 WHD plasma cutting machines, equipped with internal water cooling, offer significant advantages over air-cooled plasma systems. They effectively address issues related to torch and consumable cooling, especially at higher output powers. Unlike compressed air-cooled plasma, which relies on a high volume of airflow for cooling, OPTeCUT WHD models use liquid cooling to maintain low temperatures. This ensures a longer lifespan for cutting tips, electrodes, and torch components, surpassing that of air-cooled counterparts. With a fraction of the airflow volume, these models excel in cutting performance and duty cycle, making them ideal for various applications, including automated cutting tables, robotics, and heavy-duty manual tasks in foundries, metalworks, and recycling yards.

Standard supply & options & accessories

Cutting torch options;

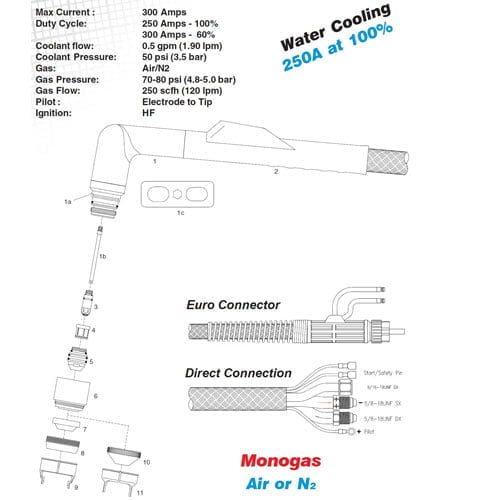

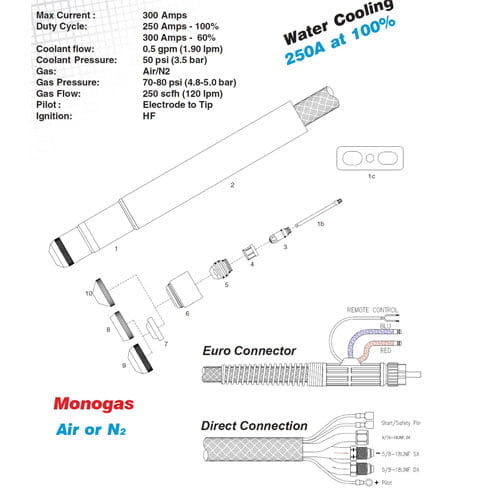

Standard torch H250W/M250W (300A rated@60%) single gas, (Thermal Dynamics type) available up to 15M. Compressed air or nitrogen gas.

Other options include; Thermacut HPR130/260 or Trafimet AW201. Single gas or dual gas options etc.

Other options;

Different input voltage, 480V, 550V etc.

Extra functions, such as remote control of cutting power etc.

Built in AVC torch height controller.

For anything special please contact our technical dept.

Reviews

There are no reviews yet.