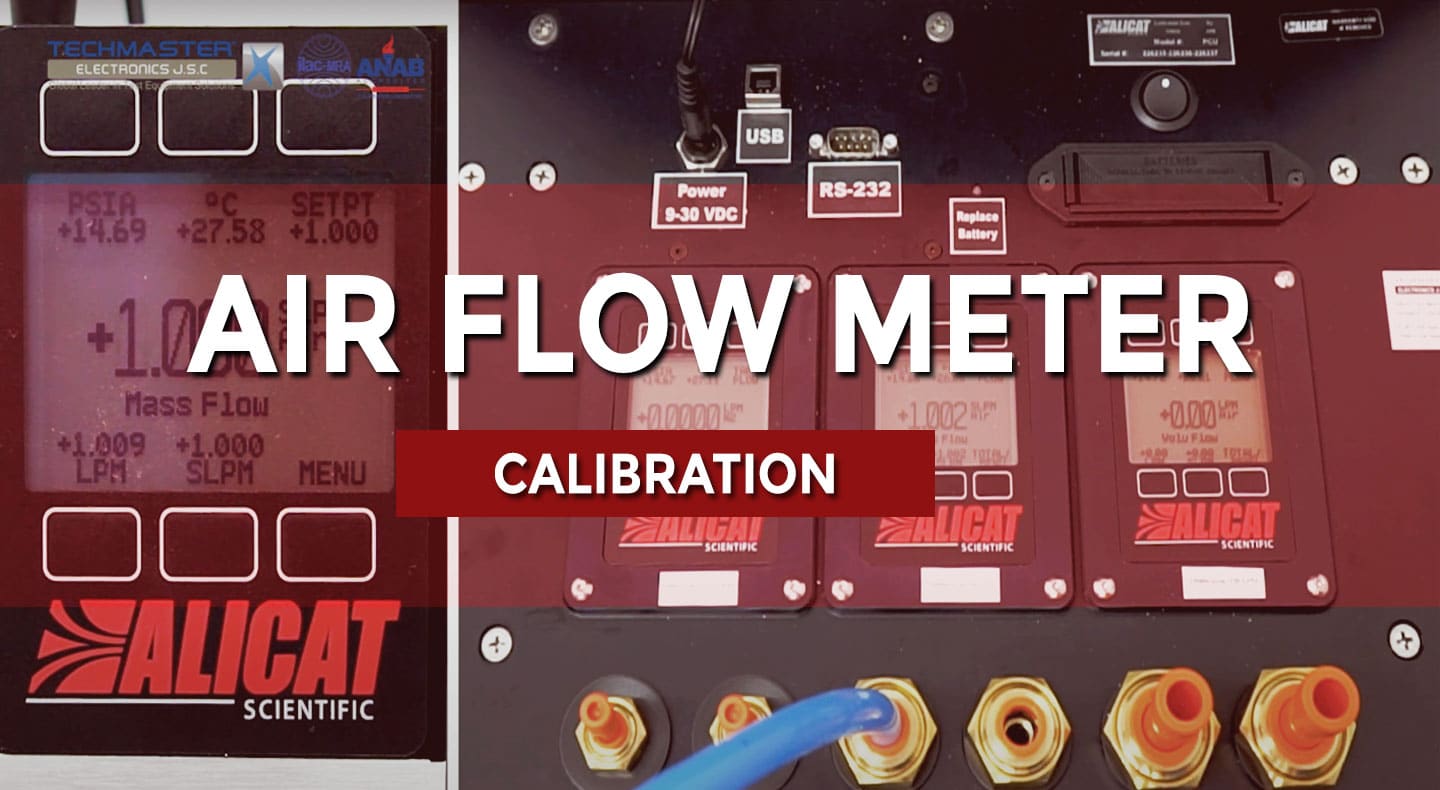

Techmaster introduce Calibration procedure for air flow meter

1. Scope of procedure

|

Unit Under Test Characteristics |

Performance Range |

Performance Method |

|

Air flow rate |

Up to 200 L/M |

Comparison to standard flow meter |

2. Standard and supporting device

– Standard Flow Meter ALICAT PCU, flow range up to 200L/min or equivalent

– Connecting tube with various size, fitting with in/out port of Unit Under Test (UUT) and standard meter (STD).

– Air flow generator range up to 200L/min or more, with flow regulator or control valve.

– Connecting tube with various size, fitting with in/out port of Unit Under Test (UUT) and standard meter (STD).

– Air flow generator range up to 200L/min or more, with flow regulator or control valve.

3. Environment conditions

– Temperature: (20 ÷ 25)oC

– Relative Humidity: (20 ÷ 65)%RH

Note: environment conditions above apply for Techmaster inhouse laboratories. Outside this bound conditions will be considered with customer for uncertainty and measurement results.

4. Preparation

– Select suitable tubes, connect Air Flow Generator – STD meter and UUT, at the suction side or arrow direction of each equipment.

– If UUT has control / adjustable valve, then connect UUT between Generator and STD meter.

– If UUT has internal pump, then Generator shall not be used. Connect UUT to STD meter directly.

– Teflon, quick-connector can be used if need.

– Ensure that system is no leak.

– Connect Air Flow Generator, STD meter, UUT to suitable power.

– Turn all on, allow warm up at least 30minutes or follow manufacturer’s instruction.

– If UUT has control / adjustable valve, then connect UUT between Generator and STD meter.

– If UUT has internal pump, then Generator shall not be used. Connect UUT to STD meter directly.

– Teflon, quick-connector can be used if need.

– Ensure that system is no leak.

– Connect Air Flow Generator, STD meter, UUT to suitable power.

– Turn all on, allow warm up at least 30minutes or follow manufacturer’s instruction.

5. Perform

– Perform test points at: 25, 50, 75 and 100% UUT range, or follow customer’s requirement.

– Press measure button on UUT and STD meter, if needed.

– Press measure button on UUT and STD meter, if needed.

– Slowly adjust flow rate output from the Generator, until STD meter reach nearly first test point.

– In case UUT has internal pump and flow setting function, then use UUT to generate test point.

– Allow for stable reading, record value of UUT and STD meter. Repeat 5 times.

– Repeat above steps for remain test points.

– Calibration now completed, set output air flow of Generator decreasing to zero.

– Turn off UUT and STD meter, take out of all components above.

6. Tolerance

– Device tolerance will be based on customer requirements, unless otherwise stated.

– If the customer has no requirements, it will be based on manufacturer specifications or other reference sources.

– If not, the tolerance ± (3% of reading +0.3%FS) will be applied.

– If the customer has no requirements, it will be based on manufacturer specifications or other reference sources.

– If not, the tolerance ± (3% of reading +0.3%FS) will be applied.