In the semiconductor electronics industry, ensuring product quality and environmental protection during the manufacturing process is of utmost importance. To address the issue of pollution in manufacturing plants, numerous advanced technological solutions have emerged. Through this article, we will introduce some modern solutions that provide effective contamination monitoring technologies, supporting semiconductor manufacturers in achieving high standards of quality and environmental preservation.

The Ultra DI® 20

Liquid Particle Counter

How meaningful is your data?

-

FEATURE

– Advanced laser optics and sensors enable detection of particles down to 20 nm (9 nm Au)

– Obtain meaningful statistical data to detect particle excursions quickly

– Fast sample cleanup shortens the time to move from one sample point to another

– Larger sample volume and low zero counts detect smaller excursions with relevant statistical data

– Compatible with ozonated water

-

CHALLENGE

The current purity of your ultrapure water system has exceeded the ability of your existing particle monitoring instruments.

-

SOLUTION

By detecting particles as small as 20 nm, the Ultra DI® 20 Liquid Particle Counter monitors your ultrapure system, providing data on the cleanliness of your nano-filtration and distribution systems, so you can be confident particles are being removed effectively.

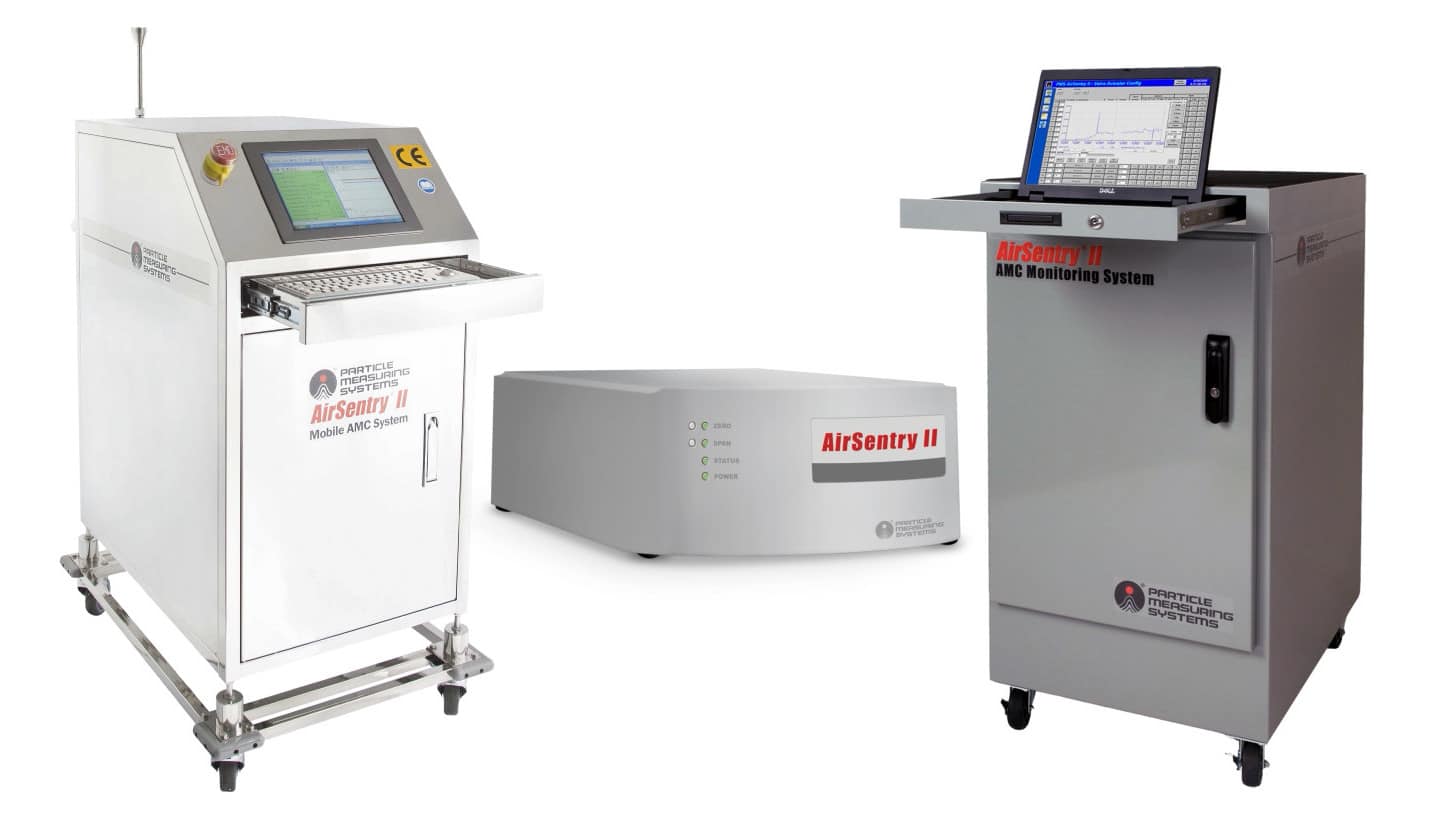

The AirSentry® II

Real-time AMC Monitoring System

Real-time AMC monitoring made simple

-

FEATURE

– Monitors airborne molecular contamination that impacts critical semiconductor processes

– Detection sensitivity to 70 ppt

– Individual analyzers to detect acids, amines, ammonia and chlorides

– Versatile product configuration

-

CHALLENGE

Molecular contamination within cleanroom and process tool environments is affecting your manufacturing processes, and you need reliable data in real-time.

-

SOLUTION

The AirSentry® Il Real-time AMC Monitoring System provides molecular contamination monitoring for acids, amines, ammonia and chlorides to detect airborne molecular contamination accurately and effectively.

The Ultrachem® 40

Liquid Particle Counter

Detect the smallest possible particles

-

FEATURE

– Measures particles as small as 40 nm in a wide variety of semiconductor process chemicals

– Has large sample volume for improved data quality

– Gives quick diagnostics and random distribution alerts on real particle events

– Has wide chemical flexibility and versatility

-

CHALLENGE

In your wafer cleaning and chemical processes, the products may encounter defects during critical stages. You need a solution that provides real-time data to better understand levels of contamination that lead to product yield loss.

-

SOLUTION

The UltraChem®40 Liquid Particle Counter gives you real-time data with accuracy and repeatability to measure and monitor nanoparticles to 40 nm.

The Lasair® III 110

Aerosol Particle Counter

What does true 0.100 µm particle detection mean?

-

FEATURE

– Real-time measurement of yield-impacting particles

– Use as mobile counter to localize source of particles

– Patented smart flow technology eliminates traditional undercounting errors in manifold sampling

– Full range of accessories for monitoring in different applications

– Actual detection of 0.1 µm particles

-

CHALLENGE

Your large cleanroom has very low particle concentration, and you need to measure airborne particulates in process areas and tools.

-

SOLUTION

The Lasair® lll 110 Aerosol Particle Counter effectively monitors low particle concentrations, and it can be combined with a 16- or 32-port manifold to monitor large areas or use onboard batteries for portable monitoring.

The Nano-ID® NPC10

NanoParticle Counter

Get meaningful data — fast

-

FEATURE

– Monitors at 10 nm with a very low zero count, enabling it to monitor extremely clean environments

– Working fluid reservoir only needs fluid replenished at about 2,000 hours of use

– Does not use n-butyl or isopropyl alcohol

– No special handling and storage requirements as are associated with alcohol-base fluids

– Internal memory can store one year of data

-

CHALLENGE

Your current optical particle counter counts zeros at 0.1 microns while particle events at smaller sizes remain undetected and affect your product yield.

-

SOLUTION

The Nano-ID® NPC10 NanoParticle Counter monitors at 10 nm with a very low zero count, enabling it to count very low particle concentrations. With its 0.1 CFM flow rate, you can achieve statistical significance faster.

▸ Watch a video about “Industry leading contamination monitoring sensitivity” here.