Seawater injection is a secondary recovery technique used in oil reservoirs to replace extracted oil and maintain well pressure. Oil reservoirs are typically found within the small pores of sedimentary rock formations, so it is imperative that the injected seawater does not contain suspended particle matter that can clog these pores and hinder oil recovery. Since untreated seawater contains significant quantities of suspended particle matter it is generally filtered prior to injection into oil reservoirs. Optical particle counters offer an accurate and reliable solution to quantify particle concentrations in filtered seawater used for injection.

Oil reservoirs contained in subterranean rock formations will be under high pressure as the porous rocks are compressed by the considerable weight of rock and Earth above. It is this high pressure that drives the flow of oil to the surface during extraction. If the reservoir pressure is allowed to drop it will slow the flow of oil to the surface and significantly reduce the oil production capacity of the reservoir. Secondary recovery techniques, such as seawater injection, allow the pressure in the reservoir to be maintained by injecting an additional fluid into the reservoir to replace oil that is extracted.

Raw, untreated sea water contains a significant amount of suspended particulate matter that can accumulate inside and block the small micron-sized pores in the reservoir rock. This will limit the amount of water that can be injected into the reservoir and significantly hinder oil recovery. To prevent this happening seawater is generally filtered to an appropriate level of cleanliness before it is injected into the reservoir.

Optical particle counters (OPCs) have been widely used in the pharmaceutical and potable water industries for their accuracy and repeatability. These same instruments can be used to verify particle levels in post-filtration sea water are within acceptable cleanliness limits. Particle measurements can be done continuously using an online particle counter or by measuring samples from multiple locations using a syringe sampler particle counter. Samples collected from multiple locations can be analyzed quickly and without the need for additional sample preparation, which maximizes sample throughput. Both measurement methods enable prompt reaction to any detected failures in the filtration process.

Complete the form here to learn more about how a syringe sampling system can be used for evaluation of particle counts in injection seawater.

Particle Counting Solutions

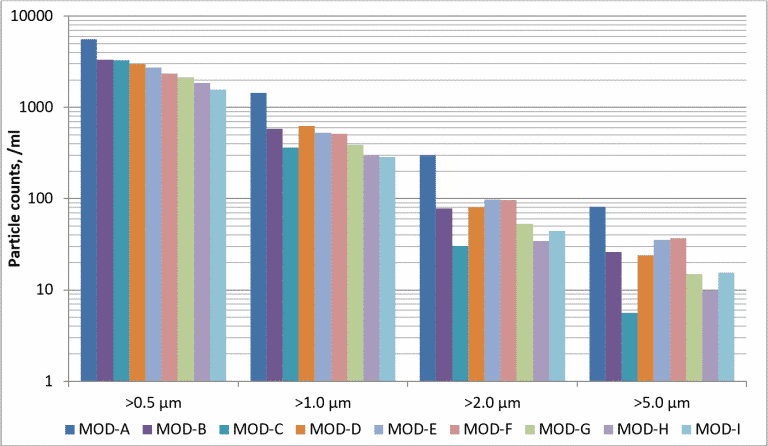

An SLS-1500 syringe sampling system, capable of measuring particles down to 0.5 µm in size, was installed in a seawater treatment facility that supplies injection water to be used for secondary recovery at several oil reservoirs. Batch samplers such as the SLS-1500 provide a versatile solution for many particle monitoring applications, with key advantages being their ease of use and minimal installation requirements. The facility takes water directly from the sea and applies several different treatment processes, including disinfection, particle filtration, and degasification, after which the treated seawater is delivered to the remote oil fields via pipelines. Particle filtration is performed using numerous horizontal deep-bed granular pressure filters, which are arranged into separate treatment modules each consisting of four filters operating in parallel with one degasification. Nine of the treatment modules were selected for the tests, and water samples were collected from the outlet of each of the treatment modules on an approximately daily basis for periods ranging from one to four weeks.

Learn more about syringe liquid particle counters.

Particle counters can also be installed in an inline configuration. Inline particle counters, such as the LiQuilaz® II, eliminate the need to manually collect and transport samples back to the particle counter for analysis, which can save considerable time and removes the possibility of samples becoming contaminated from external sources. Inline particle monitoring also allows the particle concentration to be monitored continuously and in real-time, whereas with batch samplers measurements are only made periodically and not in real-time. With continuous, real-time data from inline particle counters it is possible to configure alarms so that an alert is generated as soon as the particle concentration exceeds acceptable levels, which allows prompt remedial action to be taken.

Learn more about the Liquilaz particle counting solution.

Interested in learning more? Complete the form here to receive expert consultation.