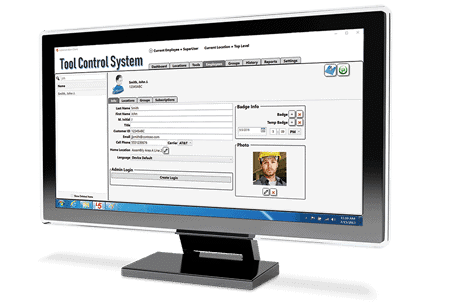

POWERFUL ADMINISTRATIVE SOFTWARE

Level 5 ATC tool boxes are networked, either wirelessly or by Ethernet and managed by powerful, easy-to-use software. The administrator can view all the boxes on the network, whether they are on or off-line, and the status of each box—including the number of tools issued, the active users, and all history. System alerts—sending email or text messages to supervisors, for example—can be customized for lost or broken tools or calibration requirements.

Custom reports can be created on each tool’s frequency of use, inspection and calibration dates, and other specific location requirements.