SPECIFICATIONS TECHNICAL ARC TECFEED ARC VOLTAGE INLINE WIRE FEEDERS, 250A, 350A & 450A

| Technical Specs | TECFEED 250i | TECFEED 350i & 450i |

| Amps rating -60% duty cycle | 250 amps | 350 amps or 450 amps for 450 model |

| Welding wire dia | 0.8-1.2mm | 0.8-1.6mm (-2.4mm for 450) |

| Wire drive system | 2 roll geared | 4 roll drive |

| Input volts | 20-110V DC | 20-110V DC |

| Weld volts range | 15-28V | 15-33V |

| Wire speed range | 2-22M/min | 2-22M/min |

| IP protection * | IP54 | IP54 |

| Approx weight | 9kg | 10kg (12kg 450) |

Introduction Technical ARC TECFEED arc voltage inline wire feeders, 250A, 350A & 450A

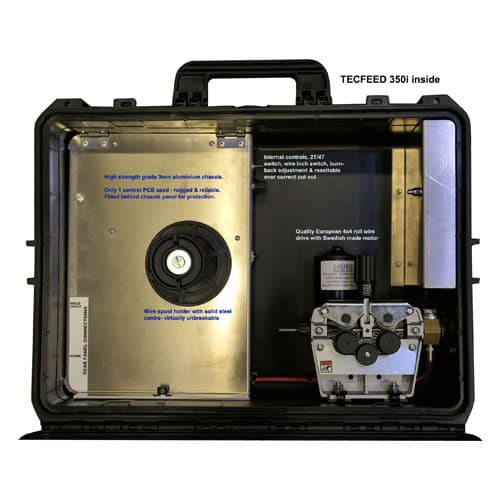

TECFEED feeders are constructed in a strong reinforced moulded case to give a fully enclosed wire feed unit which is sealed against the elements. Rugged construction & excellent portability make these models perfect for all site welding applications in even the harshest of environments. TECFEED standard size models take 300mm 15kg spool sizes, the compact versions are designed to take 200mm 5kg spool sizes. All models are fitted with a heavy duty British made contactor to allow welding up to 250A, 350A or 450A depending on model. All models allow stright polarity (standard MIG/MAG with gas) or reverse polarity (for gas less MIG).

All models are suitable for any type of MMA/stick or CC/CV output DC welding power source & can be used for MIG/MAG with gas or with self shielding wires.

TECFEED 250i – 250 amps rating, 2 roll wire drive – available in standard 15kg or compact version for 5kg

TECFEED 350i – 350 amps rating, 4 roll wire drive – available in standard 15kg or compact version for 5kg

TECFEED 450i – 450 amps rating, 4 roll wire drive – available only standard 15kg size, fitted with our largest contactor for the heaviest jobs.

Functions & features for all models; Technical ARC TECFEED arc voltage inline wire feeders, 250A, 350A & 450A

– Gas solenoid fitted.

– Heavy duty contactor fitted for non live torch.

– 2T/4T torch trigger latching function.

– Adjustable burnback control.

– Wire inching switch.

– Torch Euro connection.

Further information – CC vs CV power sources;

For the very best MIG welding performance a CV (constant voltage output) is preferred. With CV a perfect arc condition as you would expect from any good workshop MIG can be achieved permitting welding from very thin sheet material up to structual steel fabrication. Many of the more expensive engine driven power sources have CC/CV output which is the perfect solution.

However, more popular power sources tend to have only CC output designed mainly for MMA stick electrode welding. For use as a MIG welder these power sources have some limitations at lower power particuarly in dip transfer mode. The worst case is trying to MIG weld thin materials in dip transfer with a large diameter MIG wire, this can result in an unstable arc condition. If the CC power source is fitted with ‘ARC FORCE’ control this can improve the arc condition to be almost as good as as a CV power source. Also reducing the wire diameter helps arc stability at low power. At increased welding power, globular & spray transfer superb MIG welding results are achieved with a CC power.

Standard supply, options & accessories

Standard supply;

Larger case type suitable for 300mm 15kg spools, wire speed control on front, Euro adaptor, gas valve fitted, 2T/4T, burnback & inch controls inside feeder, welding cable connection at rear & 3M plug in earth signal cable included. (This connects to your welding job to provide voltage for the TECFEED).

Options at time of order;

Compact 5kg case for smaller 200mm wire reels, digital meter fitted, weld power control fitted on front to allow connection to power source remote.

Accessories;

MIG torches, weld cables, wire feed rollers to suit all popular wire sizes & types.

Reviews

There are no reviews yet.