SPECIFICATIONS TECHNICAL ARC OPTeARC EWELD 700-1000A HD CC/CV DC/AC-DC

| Model / output power |

700A model |

800A model |

1000 A model

|

| Input voltage (standard models) | 400V 3 phase | 400V 3 phase | 400V 3 phase |

| Amperage range | 50-700A@44V | 50-800A@44V | 50-1000A@44V |

| Duty cycle

|

700@80%

630A@100% |

800@80%

715A@100%

|

1000A@80%

900A@100% |

| Protection | IP23 | IP23 | IP23 |

| Maximum no load volts (OCV) | 88V | 88V | 88V |

| Input fuse size (D) 400V supply | 45/63A

(32A D type CB OK to 80% output) |

63A | 63/80A |

| Min generator size for up to ¾ power* | 27KVA | 30KVA | 40KVA |

| Approx net weight* | 240kg | 270kg | 340kg |

Approx case size all models (all models) 1040mm H X 930mm L X 520mm W (excludes exterior hardware)

*AC-DC models approx 35kg extra weight.

*Generator size for full power is 30% higher.

Introduction Technical ARC OPTeARC EWELD 700-1000A HD CC/CV DC/AC-DC

OPTeARC EWELD 700HD, 800HD & 1000HD extreme performance machines

DC output or AC-DC output.

- SUB ARC (SAW), DC & AC-DC tandem (lead & trail)

- Arc air gouging (CAC)

- MIG/MAG (MCAW) (FCAW)

- TIG (GTAW)

- MMA (ARC) (SMAW)

The EWELD HD CC/CV range are multi-process welding power sources designed for the heaviest duty welding applications. Utilising our hybrid OPTeARC technology these machines offer an unrivalled combination of extreme welding performance, very low power consumption & rugged reliable build.

With very high duty cycles these machines are perfect for sub arc welding (SAW), Arc air gouging (CAC), MMA (SMAW) welding, metal spraying, MIG/MAG (MCAW, FCAW), TIG and other applications which require very high current and duty. In addition, easy parallel connection of two machines (S2 version) allow power up to 2000A. These machines provide super smooth output power on all processes & the high OCV means all electrodes including celulosics & high gauge carbons can be run without arc drop outs.

EWELD HD power sources are available in two control options, S1 model or S2 model, in addition all versions are available as DC only or AC-DC.

S1 model versions have basic controls, welding power, CC/CV switch, arc force, inductance, remote control socket & digital meters. Ideal for MMA, gouging & can be used for all other processes like SUB ARC & MIG/MAG if a separate control box is used to drive the wire feeder etc. A 24V output is available for wire feeders & remote function can be used with our EWELD remote – basic version to control output power (V/A) or to give variable control of weld power on a wire feeder.

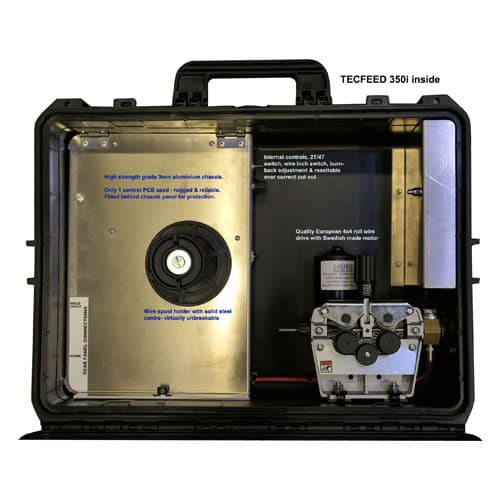

S2 model versions have the same controls as S1 but with a wire drive PCB & interface PCB fitted internally. This provides functions for our SUB ARC & MIG/MAG welding wire feeders. S2 versions can therefore directly run our SUB ARC welding head or MIG/MAG wire feeders without any additional control boxes. Additional front panel functions include, wire feed speed, burn back control & start stop of all processes. Also, a comprehensive interface/remote socket is fitted to allow use with SUBR100, 200 & 300 remotes & allow our EWELD tractor to be used with the SUBR300 remote. Furthermore, S2 models can be interfaced to PLC controllers & also allow easy parallel connection of 2 units to give up to 2000A output.

All models are manufactured to comply with BS EN 60974-1 & BS EN 60974-10

Also in full compliance with RoHS directive 2011/65/EU & weee directive 2012/19/EU

We guarantee to fully support these machines with spares & service for a minimum of 20 years, the best long term back up in the industry!

‘Invest in the best’ quality made British welding equipment. We guarantee you will be delighted!

OPTeARC EWELD 700-1000A HD models – further reading

OPTeARC EWELD 700HD, 800HD & 1000HD power sources are British-made industrial machines built using our unique Mitsubishi hybrid chopper technology. This design provides all the performance benefits of a good inverter-based machine with instant arc starts, a smooth superior arc, and very low power consumption, but with the rugged reliable build of a transformer machine.

Due to the high efficiency of our OPTeARC technology, the size, weight, and input power are reduced significantly compared to conventional machines. Furthermore, these machines tolerate harsh operating conditions such as extreme temperatures, dampness, and dust, and can be used outside in the rain. Internal construction is simple with minimal parts and only one control PCB; these machines will not fail in dirty or damp workshops like inverters do. They are not affected by fluctuations in the input supply, ensuring reliable welding year after year. Ideal for the most demanding industrial applications, offshore, oil & gas, structural steel, pipe mills, foundries, etc. All models are generator-friendly and will run from extension cables up to 100M.

Digital amp & volt meters are fitted, these show preset values then precise real time values.

MMA stick welding / arc air gouging

Super smooth performance on all electrode types. High OCV with hot start guarantees fast arc up even on dirty & rusty material. With 100% duty cycle these are ideal for demanding arc air gouging (carbon arc gouging). All types of welding electrodes cable be run with ease including cellulosic 6010 etc. Variable arc force control means you can tune the welding arc to give the very best welding characteristics for the job. A remote current control can be used to adjust the amperage up to 100m away with additional stop start of output if required. EWELD AC – DC models also allow AC MMA electrode welding with superb performance far better than any conventional AC MMA machine.

SUB ARC welding

Add our SUB ARC wire feeder/torch & control box & you have superb performance SUB arc welding suitable for column & boom mounting. Add the additional SUB ARC tractor & the package is ready for welding of beams & other linear applications. Variable inductance control on CV & variable arc force on CC means you can tune the welding arc to give the very best welding characteristics for the job. All wire sizes from 1.6mm – 6.0mm (4.0mm for 700/800A) can be run on both CC & CV. With very high duty cycles these models are ideal for continuous automatic welding.

EWELD AC-DC version are ideal for tandem SUB ARC (AC trail) etc. Frequency is variable from 10-100Hz & the output waveform is a true squarewave with instant polarity changes & the waveform can be changed from 95% negative through balanced to 95% positive to allow greater deposition or penetration.

MIG/MAG welding

Plug in a wire feed unit & you have a superb performance MIG machine with a smooth consistent arc & minimal spatter. The variable inductance control means you can tune the welding arc to give the very best welding characteristics for the job. Wire feeders can be 24V with volts & wire speed control on the feeder or inline type (across the arc). Furthermore the EWELD AC-DC models allow AC MIG welding which is sometimes required for special applications to minimise arc blow etc.

TIG welding

Plug in a TIG torch & you have a basic DC scratch TIG welder. Our optional HF TIG boxes can be supplied to provide full TIG welding functions right up to 1000A if required..

Standard supply, options & accessories – Technical ARC OPTeARC EWELD 700-1000A HD CC/CV DC/AC-DC

Standard supply for all models; 400V 3phase input, 3M mains input lead, 3M work lead, blue panels, DC only output version, lifting eyes.

Options include;

DC or AC-DC output,

S1 or S2 versions

Accessories include;

EWELD basic remote – hand remote to provide control of welding power only.

SUBR100 remote – hand remote, plug into S2 versions to give remote control of welding power & SUB ARC / MIG wire feed speed, also start/stop of process & wire inch.

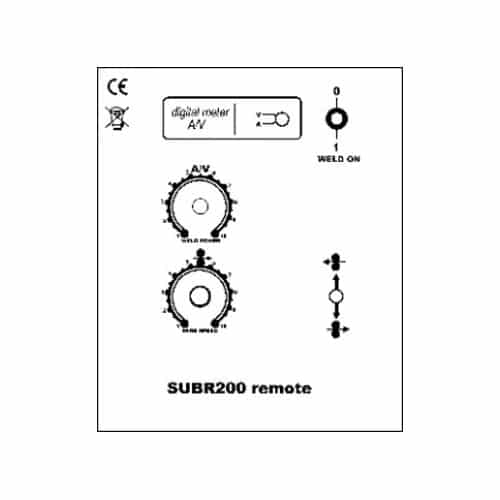

SUBR200 remote – plug into S2 versions to give the same functions as SUBR100, remote control of welding power & SUB ARC / MIG wire feed speed, also start/stop of process & wire inch + also digital read out of amps/volts. Most suited for column & boom welding.

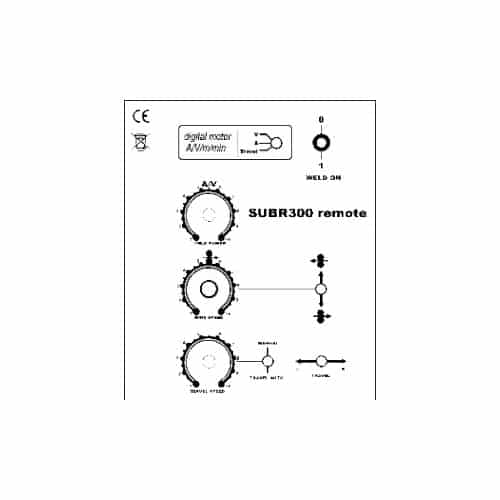

SUBR300 remote – plug into S2 versions to give the same functions as SUBR200, remote control of welding power & SUB ARC / MIG wire feed speed, also start/stop of process & wire inch + also digital read out of amps/volts + output & controls to drive our welding tractor. Ideal for mounting on the tractor.

SUB ARC welding head/wire feeder with flux hopper – used with our SUBR200 or 300

SUB ARC tractor – normally fitted with above SUB ARC welding head & used with SUBR300 remote.

Slides – single or dual (X/Y), can be used to provide adjustment of welding head position

Other accessories;

Guide rails for SUB ARC tractor, universal flux depositor tool for SUB ARC welding at up to 45 degrees.

Electrode lead & holder, ARC AIR torch, MIG wire feeder suitcase type 24V, MIG wire feeder suitcase type inline (across the arc), MIG torches, TIG torch options, foot pedal with stop/start & variable amps, TIG HF boxes.

Reviews

There are no reviews yet.