Viable Environmental Monitoring Regulations for Sterility Assurance

Updates to the European Union (EU) Good Manufacturing Practice (GMP) Annex 1 are analyzed to better understand the industry’s future trends and possible changes in guidance around viable environmental monitoring for sterilizer assurance.

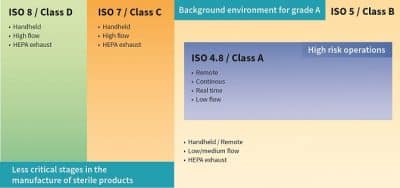

Regulations provide specifications for the selection of an effective air monitoring strategy, both directly and indirectly. With the introduction of modern manufacturing concepts and an increasing number of industry standards, there is a need to adopt viable air monitoring in conjunction with the most recent regulatory trends.

Viable air monitoring is an essential part of the classification and monitoring program of ISO 5 (Grade A) critical environments. The right combination of strategies can lead to substantial improvements, contributing significantly to cost savings programs by reducing the cost of poor quality. Key considerations include:

- Continuous vs. infrequent sampling

- Real-time vs. traditional

- Remote sampling vs. handheld devices

- Classification vs. monitoring

- Flexibility vs. single instrument

In this paper industry experts discuss these considerations and more.

Interested in learning more?

Complete the form to get the full paper.

Particle Measuring Systems (PMS) has complete cleanroom contamination control solutions for you including:

- Our Contamination Control Advisory Services who can conduct a Risk Assessment for your pharmaceutical processes

- PMS Cleanroom particle counters including portable/mobile and fixed/remote

- Microbial Monitors including portable/mobile, fixed/remote, and single use.

- Data management software from Particle Measuring Systems

Particle Measuring Systems is direct in every major market and able to ensure the same ongoing support no matter where you are located. Contact us today for a quote.