Intelligent Solutions for Optimizing Maintenance in the Food & Beverage Industry

Intelligent Solutions for Optimizing Maintenance in the Food & Beverage Industry

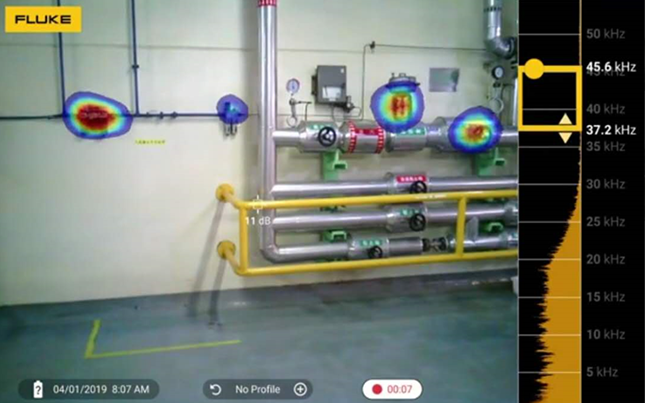

Although invisible, compressed air/gas leaks can affect product quality, production process and cause safety issues.

Leverage on Fluke’s breakthrough acoustic imaging technology to quickly & accurately pinpoint compressed air, vacuum, gas or steam leaks.

Report leaks by pictures.

Use the Fluke 1777 Power Quality Analyzer to perform:

Use the Fluke 1748/1738 Three-Phase Power Quality Loggers to perform:

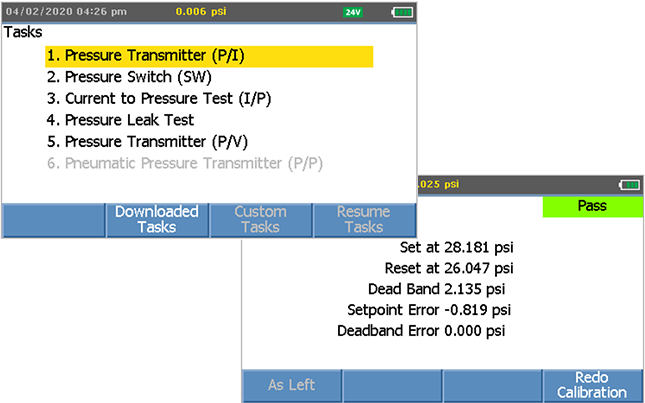

Relieve pressure testing tasks with innovative portable automated pressure calibration.

Overcome pressure testing challenges and increase productivity.

Verify particle count in cleanroom with Fluke-985.

Fluke 971 assesses temperature and humidity condition which are critical to prevent mold formation or shorten food or machine lifespan.

Fluke 922 simplifies airflow measurements that ensures proper air ventilation according to ASHRAE requirements.

Energy management

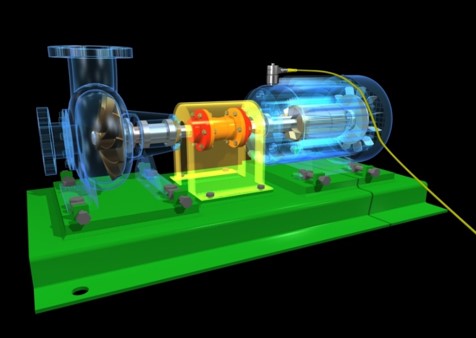

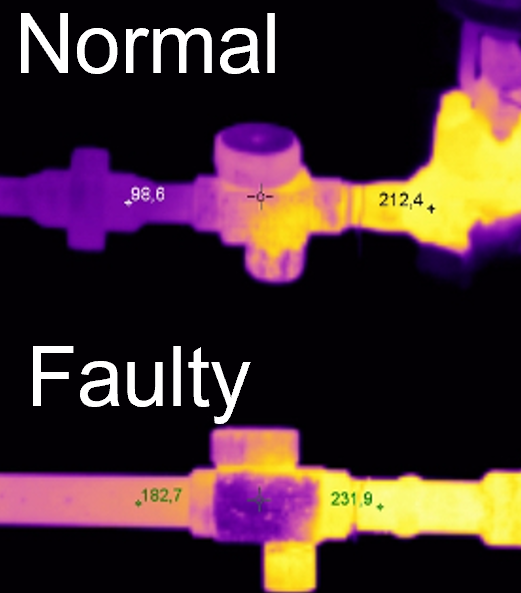

Prevent 80% of mechanical faults in the fastest possible way.

Manage energy used by electrical, mechanical or process assets through condition-based maintenance.

Enhance your reliability program while increasing productivity in maintenance.

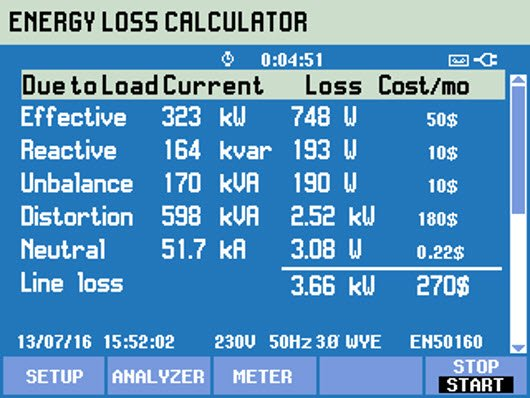

The types of energy losses are computed instantly and can be broken down into:

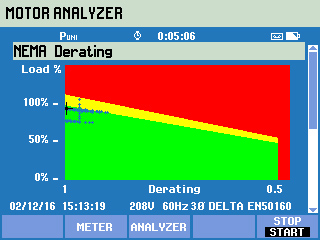

Motor mechanical load performance can be easily understood without stopping the production.

Filling, mixing, bottle cleaning and sorting operations are just some of the processes driven by compressed air.

Recover the leaks to reduce production costs and ensure healthy compressor systems.