Facility Monitoring Systems PC-based v. Industrial Automation

The scope of this document is to describe the difference between PC-based logic and industrial automation design when using Facility Monitoring Systems for cleanroom data management from particle counters, microbial monitors and other sensors.

Facility Monitoring Systems PC-based Logic Description

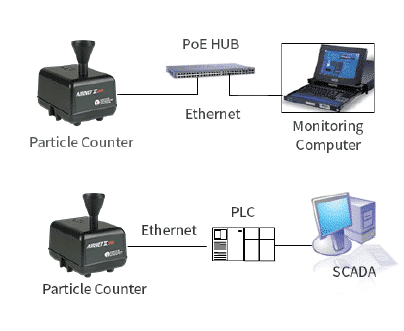

This architecture is composed of two layers:

- Sensors in the field

- PC with software to control:

- Interface

- Data storage

- Logic to manage sensors and data (alarms, warning, etc.)

The “brain” of the system is PC Pharmaceutical Net software, which is designed with this approach.

Industrial Automation Design Facility Monitoring Systems

This architecture is composed of three layers:

- Sensors in the field

- PLC/DC to:

- Perform logic

- Manage data (alarm, warning, etc.)

- Industrial software to control:

- Interface

- Data storage

The brain is the PLC/DC, a component designed to perform high reliability calculations. The FacilityPro® system is designed with this more dependable approach.

COMPLETE THE FORM TO GET THE FULL DOCUMENT

Particle Measuring Systems (PMS) has complete cleanroom contamination control solutions for you including:

- Our Contamination Control Advisory Services who can conduct a Risk Assessment for your pharmaceutical processes

- PMS Cleanroom particle counters including portable/mobile and fixed/remote

- Microbial Monitors including portable/mobile, fixed/remote, and single use.

- Data management software from Particle Measuring Systems

Particle Measuring Systems is direct in every major market and able to ensure the same ongoing support no matter where you are located. Contact us today for a quote.