OLED N2 Box Monitoring Solutions

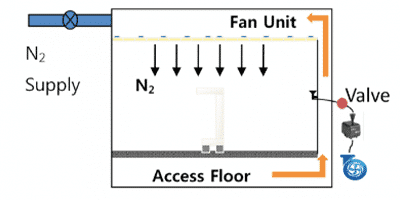

The Flat Panel Display manufacturing industry is evolving rapidly with growth driven by mobile devices and resolution improvements. Most display manufacturers are investing in Organic Light Emitting Diode (OLED) technology which offers improvements in color fidelity, contrast and power consumption over legacy TFT-LCD platforms. Compared with TFT-LCD, the OLED process is more sensitive to micro contamination, including particles, electrostatic discharge (ESD), airborne molecular contamination (AMC), volatile organic compounds (VOC), and even H2O molecules. To protect against these micro contaminants, many OLED processes and panel handling are performed in pure N2 environments. The high isolation requirements of the N2 box present challenges when attempting to monitor contamination using traditional cleanroom monitoring approaches.

Download this paper for particle monitoring solutions for small nitrogen gas production boxes.