When and how to use and set up vibration monitoring on assets

Breaking down the process and rationale for successfully adding these sensors for condition monitoring

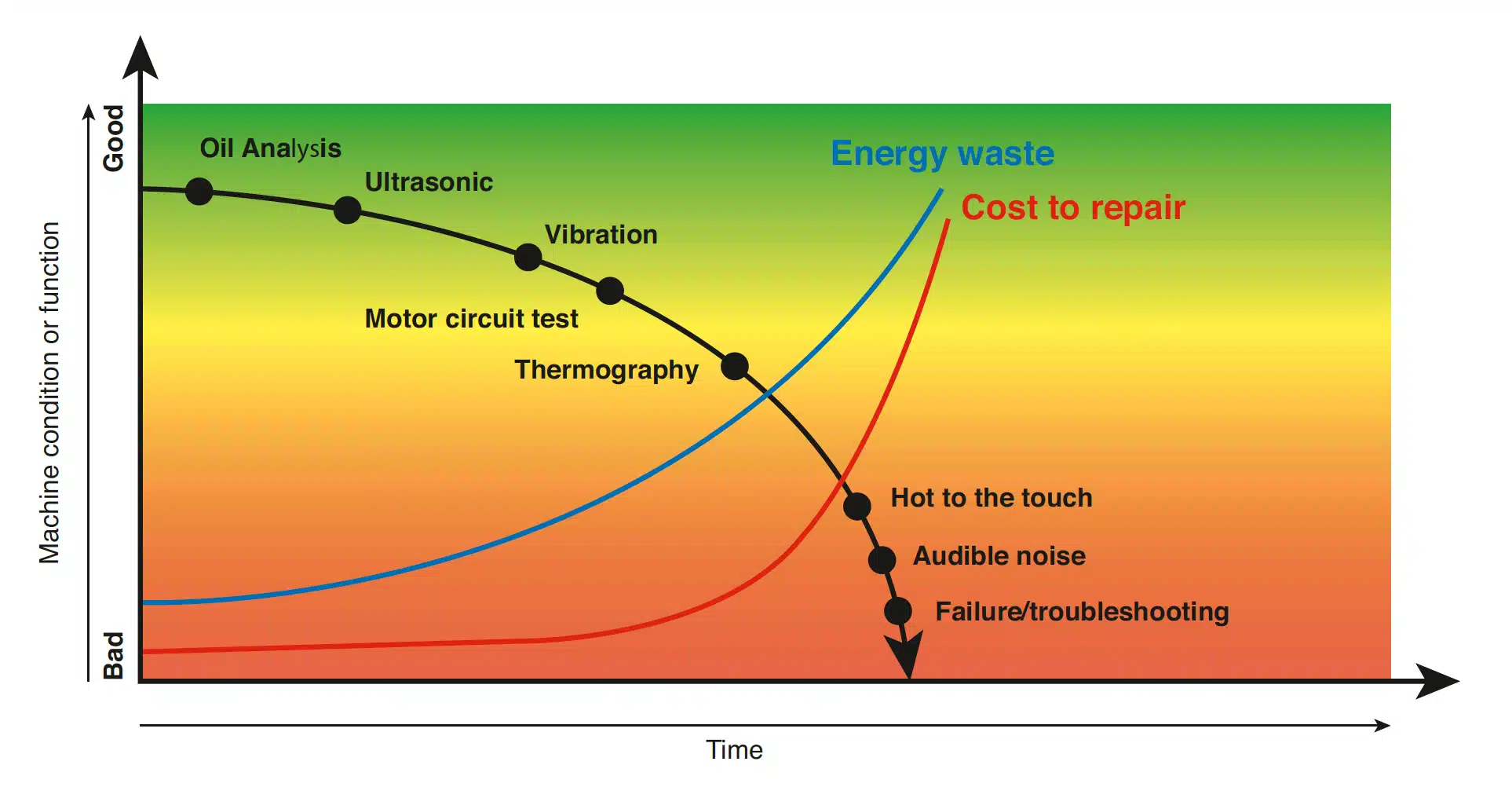

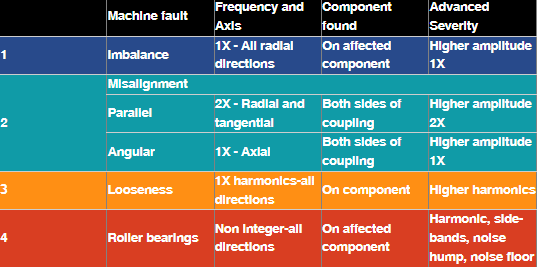

Every machine component produces a unique vibration signal. Signals displayed in the spectrum often form characteristic patterns. Pattern recognition is a key part of vibration analysis, but significant training and experience are necessary to recognize and read the patterns. Vibration analysis can watch bearing wear across 12 to 18 months as they go from slight wear (no action) to extreme wear (replace bearings immediately). Oil analysis can only be performed on oil-cooled bearings (fewer and fewer are used every day). Ultrasound finds bearing wear too early to replace the bearings (use to know when to grease the bearings instead).

Table 1 is a simplified overview of the patterns used to recognize the four most common machine faults, particularly in rotating assets.

Vibration screening can identify abnormalities caused by most of these faults as they begin — in the early stages, providing precipitous warning of impending failure. The severity of the four common faults can be tracked over time based on the history from hundreds of thousands of machines that have been analyzed by many vibration experts over 30 years. This knowledge and experience have been incorporated into rule-based algorithms and a baseline database that have been proven to be effective on standard rotating machines — motors, pumps, fans, compressors, blowers and single-shaft spindles.

Handheld vibration meters can be used for route-based, preventive strategies. A more flexible method is screening with continuous remote, wireless sensors. Regardless of the method used, vibration technology can provide reliability and maintenance teams with actionable data that can help determine when further analysis is required to decide when steps such as relubrication, repairs or replacements should be made.

Triaxial sensors are placed on assets throughout the facility, perhaps initially focusing on problem equipment to determine the best way to improve their operation. Application is simple, and setup can typically be completed in under an hour. All rotating machines can experience vibration. Pumps, fans and motors have different faults that vibration screening can identify. For a complete list of equipment that may benefit from vibration screening, see “Ideal assets candidates for vibration screening” in this article.