Optical Particle Counter Efficiency and Resolution

Optical Particle Counter efficiency and size resolution are important concepts to understand when discussing the performance of a particle counting system. These concepts and how they apply to a particle counter are described here. This paper answers some questions that arise during the selection and use of Optical Particle Counters (OPCs or

particle counters):

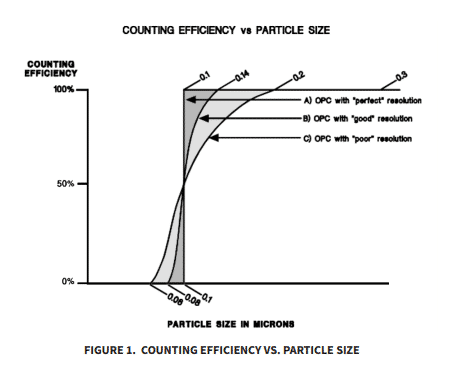

- What is counting efficiency and why should it be 50% at the most sensitive sizing threshold?

- What is the meaning of OPC resolution and why is it important?

- How will counting efficiency affect data for actual particle distributions in cleanrooms as compared to data from monodispersed calibration particles?

Most OPCs use a light source to illuminate a sample volume, an optical system to collect the particle’s scattered light pulse, a process to convert the scattered light into an electrical signal, and electronics to correlate particle size with the scattered light pulse. While the specific design varies greatly between manufacturers (and while the instruments vary with different sensitivity and flow rates), the fundamental principles of OPC operation are quite similar across the industry.

Interested in learning more?

Complete the form to get the full paper.

Particle Measuring Systems (PMS) has complete cleanroom contamination control solutions for you including:

- Our Contamination Control Advisory Services who can conduct a Risk Assessment for your pharmaceutical processes

- PMS Cleanroom particle counters including portable/mobile and fixed/remote

- Microbial Monitors including portable/mobile, fixed/remote, and single use.

- Data management software from Particle Measuring Systems

Particle Measuring Systems is direct in every major market and able to ensure the same ongoing support no matter where you are located. Contact us today for a quote.