In the current market, permissible error for torque calibration systems is commonly 1% of measured value. However, The Snap-On TTC2000 system has a low permissible error of 0.25% of the measured value.

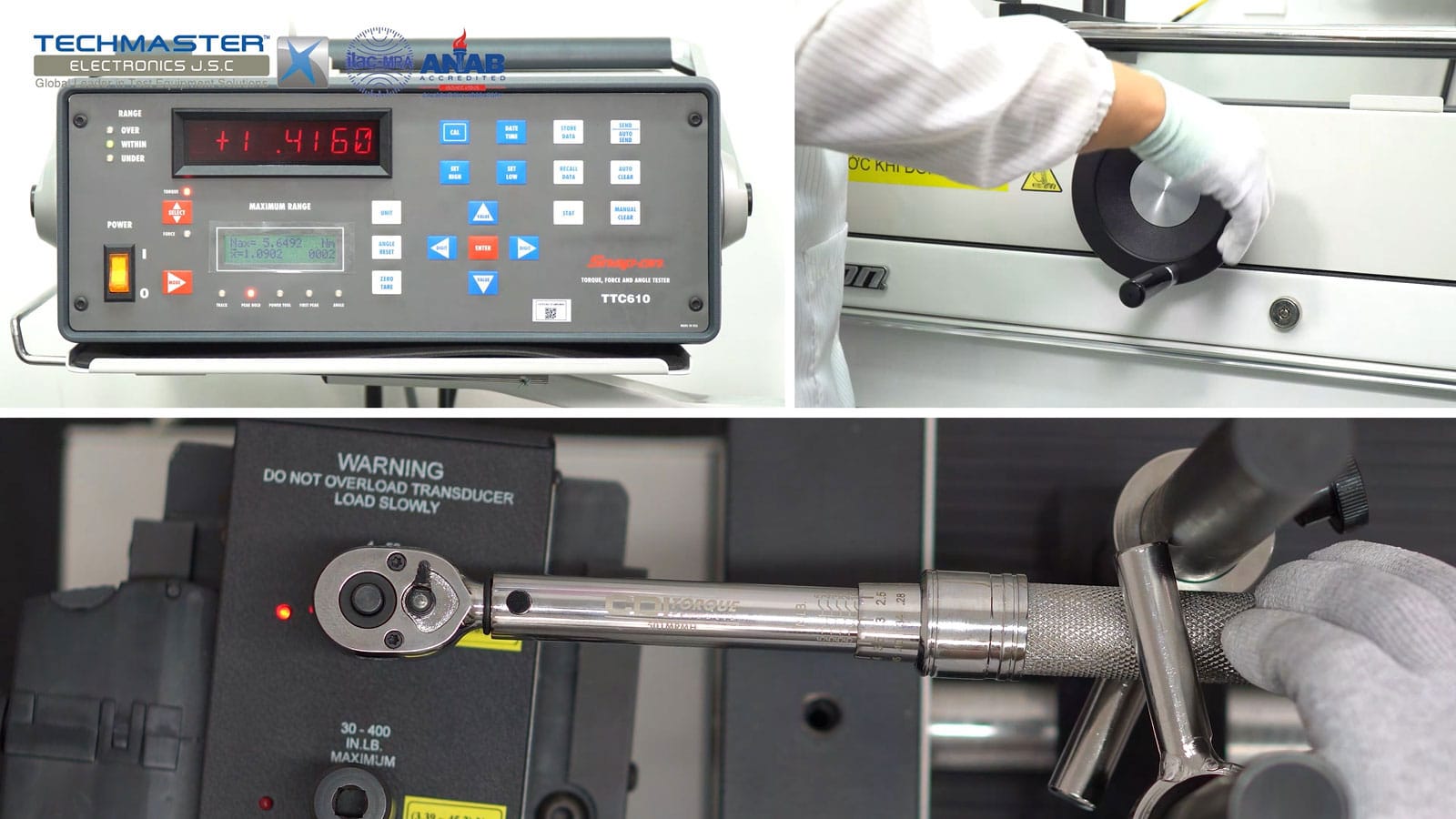

Explore torque measuring tool calibration with Snap-On TTC2000 system with Techmaster (Calibration of torque measuring Instruments by the Snap-on TTC2000 system).

1. The calibration steps

- Calibration of torque measuring Instruments by the Snap-on TTC2000 system

1.1 Calibration equipment

- Standard equipment

– Snap-On TTC2000 Electronic Torque Calibration System

– The transducers corresponding to the measurement ranges are as follows: (0.45-5.65) N.m, (27.1-339) N.m, (81.3-813) N.m, (271-2710) N.m

- The Measuring instruments to be verified

– The torque measuring tools within the calibration range of the SNAP-ON TTC2000 calibration system.

1.2 Calibration environmental conditions

+ Calibration conditions for Torque using the Snap-On TTC2000 system.

– Temperature: (23 ± 5) ºC, with a stability of ± 2 ºC during the calibration process.

– Humidity: ≤ 80% RH, with a stability of ± 5% RH during the calibration process.

1.3 Perform calibration

– Starting up the electronic torque calibration system

– Select a standard sensor with a suitable measurement range for the measuring instrument being checked.

1.3.1 Perform torque measurement verification within the ranges of (0.45-5.65) newton-met and (27.1-339) newton-met using the corresponding measuring instruments

– Attach instrument to calibration system per manufacturer’s instructions.

– Adjust the measurement unit of the calibration system to match the measurement unit of the measuring instrument.

– Verify at 5 evenly spaced points as required by the customer, with 5 repetitions per point.

– Perform verification in both clockwise (CW) and counterclockwise (CCW) directions. If the measuring instrument is single-directional, verify only in that specific direction.

– Print the results after each measurement.

– Compare the average measured values from the calibration system with the set or displayed values of the torque measuring instrument.

1.3.2 Verify the measuring instrument within the range of (81.3-813) newton-met

– Replace the transducer with the corresponding measurement range mentioned above.

– Perform a similar verification following the same steps as mentioned above.

1.3.3 Verify the measuring instrument within the range of (81.3-813) newton-met

– Replace the transducer with the corresponding measurement range.

– Repeat the same verification process as mentioned above.