CDI Master Torque Calibration Systems: Expert Torque Management & Tool Testing

In today’s industries, precise torque is vital. It is not just a preference. Instead, it is a strict necessity. From automotive lines to aerospace engineering, reliability hinges on correct torque. Thousands of products and processes rely on it. Here, a CDI Calibration System emerges. It offers a comprehensive solution. This torque calibration system ensures accuracy. Furthermore, it helps your precision torque tool perform efficiently. This article delves into its features. We explore benefits of these advanced CDI Torque Testers.

The Critical Role of Torque Wrench Calibration

Torque, in essence, is rotational force. We apply it to an object. In manufacturing and maintenance, applying the correct torque is crucial. Under-tightening causes loose connections. This can lead to potential failures. Conversely, over-tightening damages components. It results in costly repairs. Also, it creates safety hazards. Therefore, regular torque wrench calibration proves essential. We calibrate torque wrenches. We also calibrate screwdrivers. Other torque-applying tools qualify too. This process helps:

- Ensure Torque Accuracy: Applied torque must match specifications.

- Maintain Consistency: Achieve uniform results across applications. This includes multiple operators.

- Enhance Safety: Prevent failures from improper torque use.

- Comply with Standards: Meet industry regulations. This includes quality control requirements for torque management.

Introducing CDI Calibration System: Precision & Efficiency

CDI Torque Products belongs to Snap-on Incorporated. They are a recognized leader. They develop and manufacture high-precision torque instruments. A CDI Calibration System represents pinnacle technology. This torque calibration system offers excellence. These CDI Torque Testers meet modern industry’s demanding needs. These solutions provide many features. They design for accuracy, efficiency, and easy use.

Exploring Core Features of CDI’s Calibration Technology

CDI delivers many outstanding features. They optimize torque wrench calibration.

Comprehensive Testing Capabilities

A CDI Calibration System can test many tools. It calibrates click-type torque wrenches. Dial and digital wrenches also qualify. Torque screwdrivers and multipliers are included. Cable tensiometers receive support. Even non-impact power tools are calibrated. These torque testers serve all requirements. They handle a wide torque range. Capabilities go from tiny inch-ounces. They reach up to thousands of foot-pounds. This ensures overall torque accuracy.

Automation for Enhanced Precision

Many CDI Calibration System models feature “Smart” Transducers. They automatically recognize sensors. This simplifies the setup process. Furthermore, it minimizes human error. These torque calibration systems design for precision. They usually offer ± 0.25% accuracy. Or, often, even better than the indicated value. This ensures trustworthy results.

Intuitive Interface & Robust Data Management

Despite sophistication, these systems are user-friendly. They often have intuitive interfaces. Digital displays are very clear. Operations are straightforward. Advanced models boast many features. They include built-in printers for instant documents. They have date and time stamping. This ensures full traceability. Strong statistical analysis capabilities exist. They offer in-depth performance insights. This supports effective torque management.

Versatile Measurement Units & Durable Construction

CDI Calibration System solutions support many units. They meet global standards. These include in. oz., in. lb., ft. lb., Nm, dNm, cNm, mkg, and cmkg. Every CDI Torque Tester builds very robustly. They design for industrial environments. This ensures durability. Furthermore, they offer long-term reliability.

Unlocking Tangible Benefits with a CDI Calibration System

Investing in a CDI Calibration System brings many benefits. This holds true for any organization. Especially those relying on precision torque tool application.

Increased Operational Efficiency

Streamlined torque wrench calibration processes exist. Automated features are highly effective. They significantly reduce time and effort for tool calibration. This leads to increased operational efficiency.

Lowered Overall Costs

Ensuring torque accuracy is key. Preventing over-tightening is also vital. These torque calibration systems help minimize component damage. They reduce costly rework and repairs. Furthermore, in-house calibration capabilities exist. This eliminates or reduces external service expenses.

Enhanced Standardization and Compliance

A CDI Calibration System helps organizations maintain high standards. This is true for torque management processes. It ensures compliance with internal quality rules. It also meets external industry regulations (like ISO and ASME).

Improved Data Retention and Traceability

Storing calibration data is important. Retrieving it provides valuable historical records. This is essential for audits. It supports quality control analysis. Preventive maintenance planning also benefits greatly.

Increased Equipment Lifetime

Ensure tools operate correctly. They must stay within specified parameters. Identifying issues early is also crucial. Regular torque wrench calibration helps extend lifespan. It prolongs the life of valuable torque equipment.

Elevated Product Quality and Reliability

Ultimately, using accurately calibrated precision torque tool devices leads to higher quality. Products improve. Reliability also increases. This enhances customer satisfaction. Furthermore, it boosts brand reputation.

Prominent Torque Tool Brands Calibrated by CDI’s Systems

A CDI Calibration System is renowned for versatility. It calibrates a wide array of torque instruments. This holds true regardless of the manufacturer. CDI Torque Products is a Snap-on brand. However, their torque calibration system is highly flexible. They design to service many leading brands.

Due to their sophisticated design and wide torque range. These CDI Torque Testers possess various adapters. Furthermore, they include different fixtures. CDI’s calibration technology can calibrate most torque tools. Specifically, they calibrate from most major professional brands.

List of Representative Brands

-

Snap-on:

As the parent company, Snap-on torque tools are fully compatible.

-

CDI Torque Products:

Their own brand makes high-precision tools.

-

Craftsman:

This is a widely recognized brand. It serves both professional and consumer markets.

-

Proto:

Known for durable industrial hand tools.

-

Mac Tools:

A popular choice among automotive professionals.

-

Matco Tools:

Another leading brand in the automotive service industry.

-

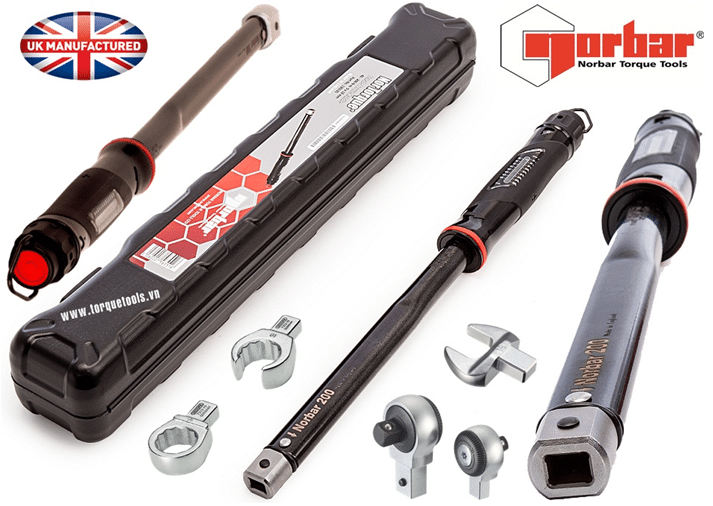

Norbar:

A specialist in torque control and measurement.

-

Stahlwille:

A German manufacturer of high-quality hand tools. This includes torque wrenches.

-

Gedore:

Another prominent German tool manufacturer. They offer a comprehensive torque tool range.

-

Tohnichi:

A Japanese brand known for precision torque equipment.

-

Mountz:

Specializing in torque tools and solutions. Specifically, for manufacturing.

-

Seekonk Precision Tools:

Known for their preset and dial torque tools.

-

Sturtevant Richmont:

A long-standing name in torque control. Furthermore, they are known for measurement.

-

Tekton:

Offering a range of tools. They are known for their value.

-

Husky:

A brand commonly found in home improvement stores.

-

Kobalt:

Another brand prevalent in the home improvement sector.

-

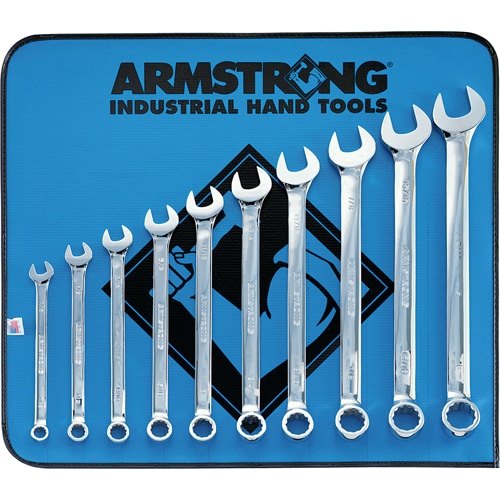

Armstrong:

A brand with a history. Specifically, in industrial tools.

-

SK Tools:

Known for their American-made professional tools.

It’s important to note this versatility. However, specific CDI Calibration System models vary. Compatibility also depends on correct adapters. Or, possibly, on available fixtures. Nevertheless, the core design principle of a CDI Calibration System is clear. It provides a comprehensive solution. This serves laboratories. Also, it serves industries. These handle diverse torque equipment. They build to test and calibrate various tools (click-type, dial, digital, screwdrivers, multipliers). This torque calibration system operates across a wide range of torque values. This makes them suitable. They fit the vast majority of professional torque tool brands.