High-Purity Process Chemical

High-Purity Process Chemical Particle Contamination Control has become increasingly complex due to nanometer technology.

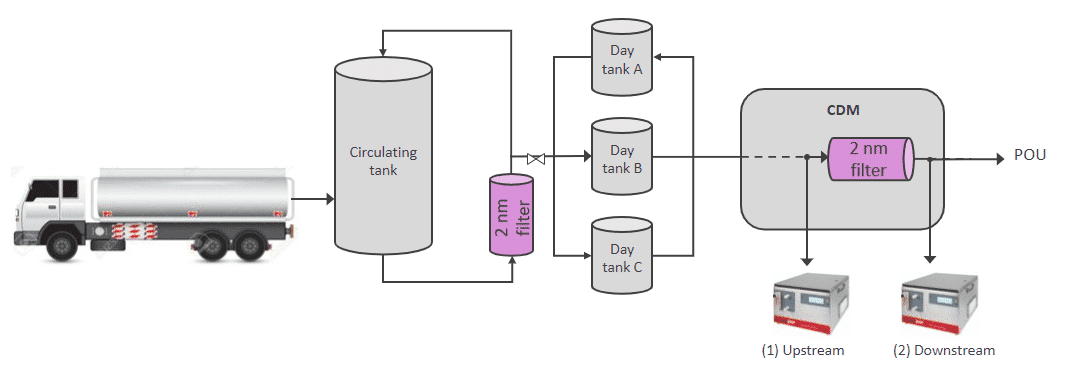

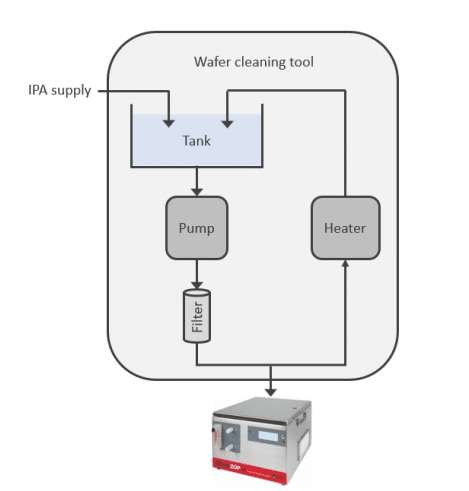

As semiconductor devices become increasingly complex, and the critical particle size for today’s leading-edge technology nodes decreases into the sub-10 nm size-range, the control and mitigation of potentially yield-impacting particle contamination at the smallest possible particle size becomes ever more crucial. Until recently, there has been a significant sensitivity gap between the critical particle size and the detection limit of traditional chemical particle counters. With industry-leading 20 nm sensitivity, the Chem 20™chemical particle counter provides a comprehensive solution for the control and mitigation of particle contamination at 20 nm in ultra-pure chemical applications. The use-cases presented here show how the Chem 20 can be utilised throughout the microelectronics industry in a variety of applications at semiconductor manufacturers, chemical suppliers, and at tool and component suppliers.

The detection and elimination of yield-impacting particle contamination in high-purity process chemicals has been a continuous challenge in the semiconductor industry, and this challenge is becoming increasingly imperative as the critical particle size for modern technology nodes decreases to 10 nm and smaller. Traditional chemical particle counters, typically limited in sensitivity to particles around 30 to 40 nm in diameter or larger, no longer provide sufficient sensitivity for modern high-end process chemical applications. However, thanks to recent advances in laser optics and detector technology, the Chem 20 chemical particle counter provides particle sensitivity down to 20 nm in process chemicals, with 9 nm sensitivity in the case of metallic particles. This makes the Chem 20 the world’s most sensitive in-line chemical optical particle counter, providing real-time, actionable 20 nm particle data suitable for a wide range of high-purity process chemical applications throughout the microelectronics industry.

Since the performance of chemical particle counters is influenced by the refractive index of the chemical being measured, the Chem 20 is available in two configurations to ensure that optimal particle sensitivity is achieved in every application. The standard Chem 20 is optimised for low refractive index fluids including water, hydrofluoric acid, hydrogen peroxide, and ammonium hydroxide, while the Chem 20-HI is optimized for higher refractive index fluids including hydrochloric acid and sulphuric acid.

For high-sensitivity optical particle counters such as the Chem 20, a chemical media’s background light scattering, often referred to as molecular scattering, can become a significant problem. For some chemicals it can overwhelm the optical detector and prevent the detection of light scattered from particles. The Chem 20’s High-Scatter mode detects particles in many high-scattering chemicals that would otherwise be impossible, providing industry-leading particle sensitivity in the widest range of different process chemicals.

This application note presents a selection of applications that demonstrate how the Chem 20 particle counter can be a valuable tool for the control and mitigation of High-Purity Process Chemical Particle Contamination down to 20 nm.

Interested in learning more? Complete the form here to receive expert consultation.