Monitoring particles in process chemicals helps to improve yield. High particle levels in process chemicals have been shown to directly affect product quality. The need for continued reductions in particle size and quantity in cleanroom environments is well established. The International Technology Roadmap for Semiconductors (ITRS), sponsored by the United States Semiconductor Industry Association (SIA), defines the need for persistent decreases in particle levels in process gases, water, chemicals, and air in order to meet future generation technology nodes. The ability to accurately measure these contaminants is the first step in developing a comprehensive particle control plan.

While numerous techniques are available to monitor and characterize particulates, most require significant off-line analysis and interpretation. This usually reduces the number of measured samples resulting in fewer data points and time delayed results. Liquid Particle Counters (LPCs), based on light scattering, are widely used for continuous on-line particle monitoring of process chemicals. Proper selection and implementation of a liquid particle counter are important for ensuring data integrity.

Although the design, performance, and specifications of LPCs may differ, a few key principles remain the same. First, particle counters do not directly count particles. Particle counters based on light scattering are designed to measure the equivalent optical size of particles as referenced against a calibration standard. In most cases, that standard is a polystyrene latex sphere (PSL). These are readily available and National Institute of Standards and Technology (NIST) size traceable.

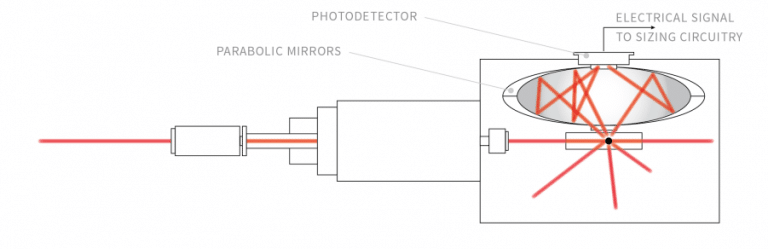

Laser light, with wavelengths usually between 600-800 nm, is used to illuminate the sample cell or capillary. As individual particles traverse the laser beam, light scattering occurs because of the index of refraction difference between the transport media and the particle. The amount of scatter depends on many factors but is largely dependent on the particle size, shape, and index of refraction.

Scattered light is then collected and focused onto a photodetector where the signal is converted into an electronic pulse.

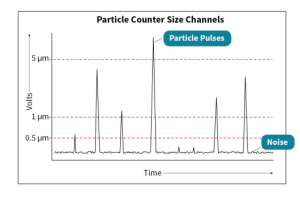

The dashed lines represent the voltage values or channels defined for each particle size during calibration with PSLs.

Each pulse represents an individual particle, while the magnitude of the pulse determines its size by comparing the PSL equivalent amount of scatter.

Interested in learning more? Complete the form here to receive expert consultation.

Find a solution for monitoring particles in process chemicals:

- Process Chemical Monitoring: 20 – 100 nm

- Batch sampling for process chemicals

- Reliable solution for cost sensitive needs