Ultra-pure water particle measurements can take a long time to return to a stable baseline after an event interruption. Learn about factors affecting stabilization time.

Modern ultra-pure water (UPW) systems must be purified to meet the increasingly stringent standards of high-end manufacturing processes. It is common to see  high-end UPW systems containing particle concentrations in the single-digit particle/ml range or lower for particles larger than 20 nm. Monitoring particles in a UPW system is crucial to ensuring the particle level remains below acceptable control limits and does not threaten production.

high-end UPW systems containing particle concentrations in the single-digit particle/ml range or lower for particles larger than 20 nm. Monitoring particles in a UPW system is crucial to ensuring the particle level remains below acceptable control limits and does not threaten production.

When the steady-state “baseline” particle level is low, the time taken for particle counts to return to the baseline level can be considerable and can be attributable to major interruptions such as shutdowns to perform maintenance and install new components or sample lines to the system’s regular operation. Depending on the size and complexity of the system, the stabilization period can last for several weeks or even months. In addition, the high-sensitivity particle counters required to monitor particle levels in UPW systems need time to reach a stable operating temperature after powering up. During this initial warm-up phase, the particle counts reported by the particle counter may be temporarily elevated before decreasing to the actual level as the instrument reaches thermal stability.

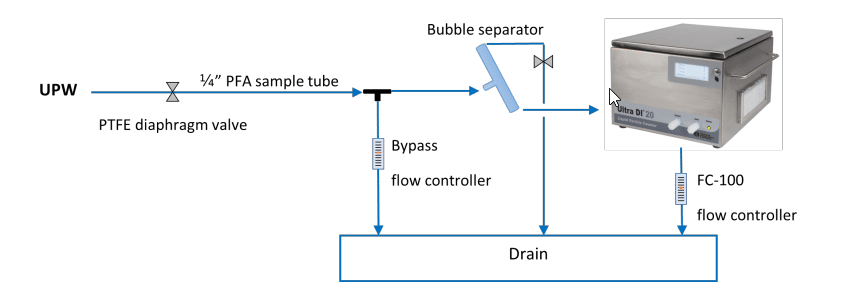

This application note presents the results of an evaluation performed using an Ultra DI® 20 (UDI-20) Liquid Particle Counter to investigate various factors that influence the stabilization time of particle measurements in a UPW system. Factors tested include the warm-up period after powering on, the effect of disconnecting and reconnecting sample tubes and renewing the flared connection, the clean-up time after installing new sample tubes of various lengths, and the clean-up time after installing a new PFA diaphragm valve. These findings should help the reader understand why UPW systems can take a significant amount of time to clean up after an interruption and which factors are likely to have the most significant influence.

In this paper, an Ultra-DI 20 Liquid Particle Counter instrument is used to characterize the clean-up time after various actions.