Optical and condensation particle counters are the two main types of particle counters used for detecting and counting aerosol particles.

Optical Particle Counters

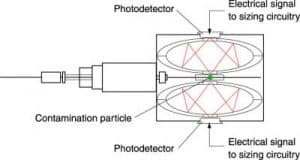

Conventional optical particle counters (OPCs) use light sample cells to detect, count, and measure airborne particles. OPCs do this by measuring the light scattered by each particle. As a particle passes through the OPC’s sample cell, the particle is illuminated by a high-energy light source: usually a laser beam. Some of the incident light photons may be absorbed or scattered by the particle, and depending on the operating mode of the OPC, the amplitude of absorbed or scattered light is measured. PMS offers a wide variety of OPCs that suit various needs. These include the Lasair Pro, Lasair III 110, Airnet II, and IsoAir Pro-Plus to name just a few.

OPCs are commonly used for counting large particles and have a lower size limitation of around 100 nm. Detecting particles with diameters smaller than 0.1 µm is very difficult due to the inherent sensitivity limitations of photodetectors.

Condensation Particle Counters

Condensation particle counters (CPCs) solve the problem of counting ultra-small particles by using a condensation process to physically grow particles the apparent size pf the particles so that they can be detected using an OPC sample cell. The thermodynamic process that enlarges the particles within the CPC instrument allows the particles to be detected by a traditional OPC sample cell. This allows users to measure particles that are as small as 10 nm (see the NanoAir™ 10 Condensation Particle Counter).

CPCs utilize a working fluid that forms a saturated vapor that can be condensed onto the nanoparticles before they move through an OPC sample cell. The working fluid is brought to a precisely controlled temperature in a chamber inside the instrument to form the necessary supersaturated vapor. As the aerosol particles are sampled and drawn through the chamber with the vaporized working fluid, the particles are brought to the correct temperature and pressure and the nanoparticles are mixed thoroughly with the vapor molecules.

After the vapor and aerosol are mixed, the mixture is cooled. This creates a supersaturated vapor that can now condense on the nanoparticles which act as condensation nuclei, allowing the vapor to form liquid layers of the working fluid on each particle as the vapor condenses. The NanoAir’s use of a proprietary, non-volatile working fluid greatly decreases the consumption and need for maintenance and refills.

The liquid droplets that now encapsulate the nanoparticles are then drawn through the OPC sample cell where they are counted using light scattering measurement techniques.

Interested in learning more about aerosol particle counters? Complete the form here.