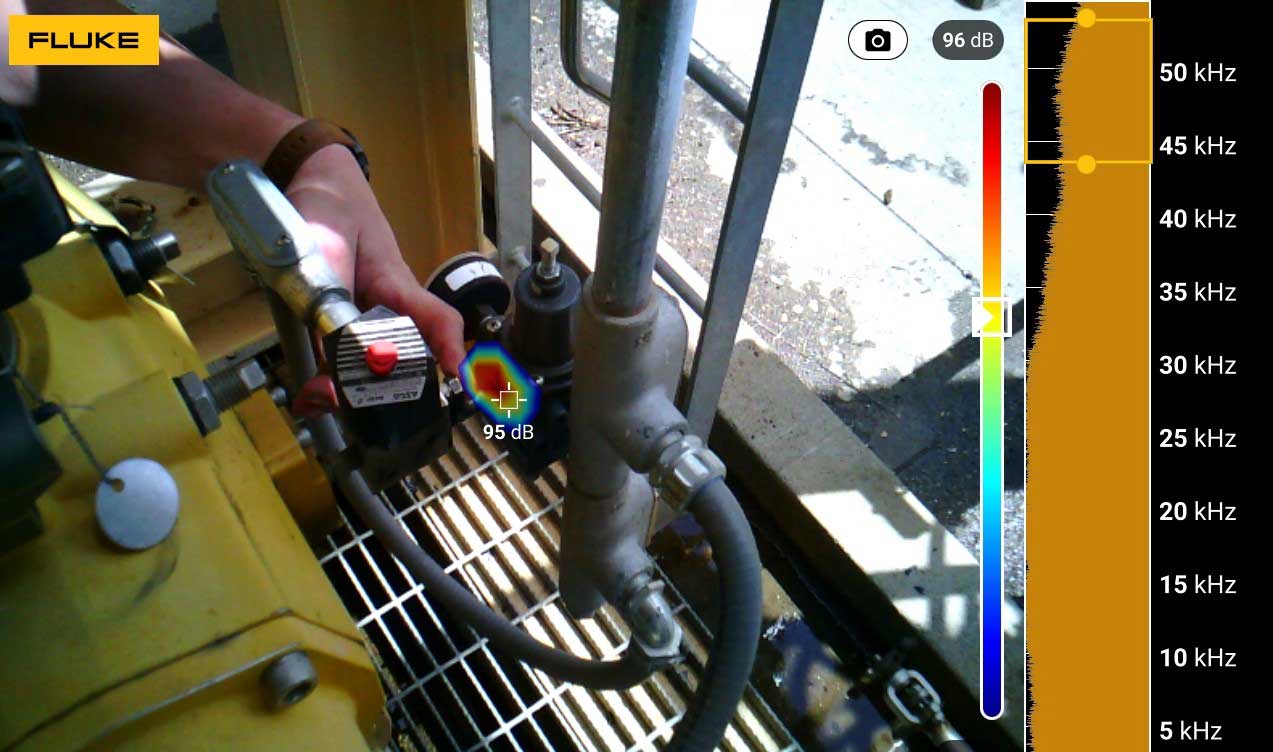

1. Control Air Pressure Regulator Failu

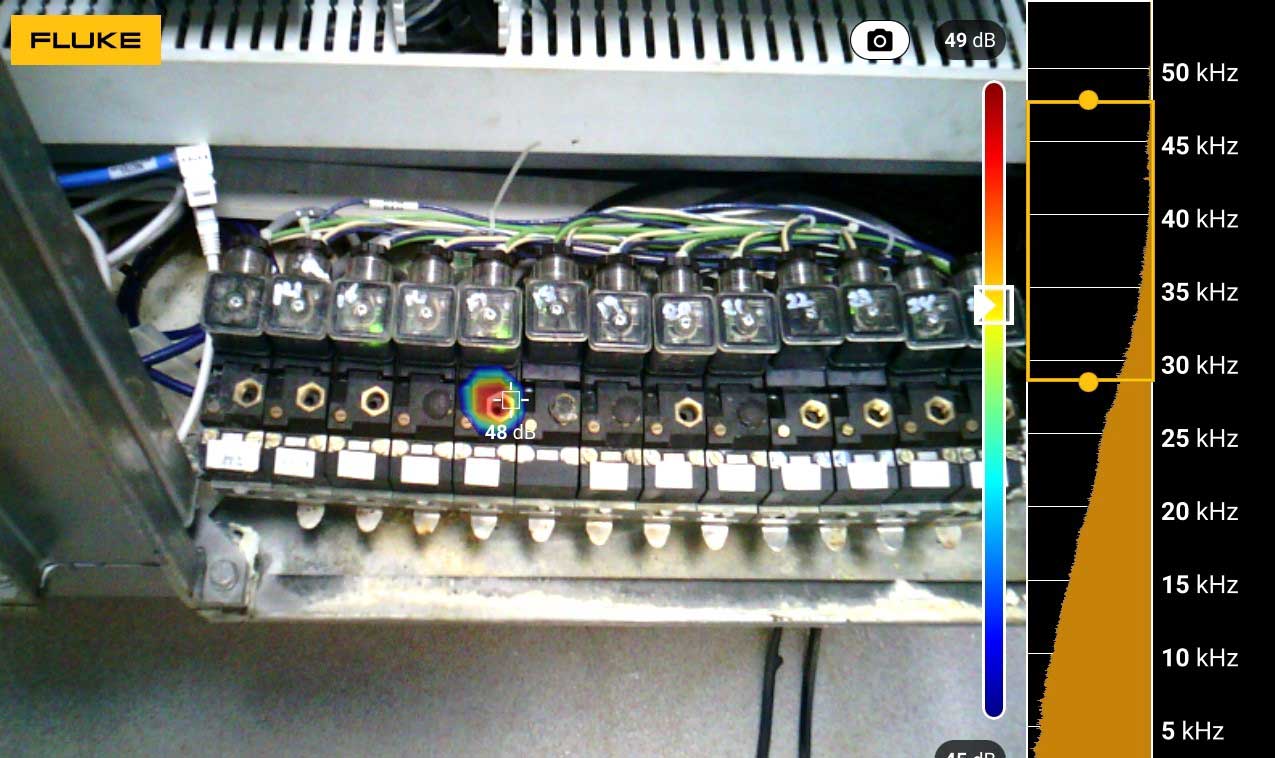

2. Process Control Valve Panel Condensation

This control panel is for a process valve (electric and pneumatic). This customer complained of an unfounded electrical failure. It turns out, the root cause wasn’t electrical at all. The Fluke ii900 identified a compressed air dryer that was not operating efficiently, which caused condensation in the area and eventually caused the electrical components to fail.

3. Pressure Regulator Corrosion

A pressure regulator that has corroded badly and is no longer functioning. The regulator was part of equipment that had compressed air, nitrogen, and carbon dioxide. This customer had a pressure regulator continuing to fail but couldn’t figure out where. The Fluke ii900 pinpointed small carbon dioxide leaks nearby which over time can cause components to break, negatively impacting uptime and/or quality. The root cause of many failures that go unnoticed.

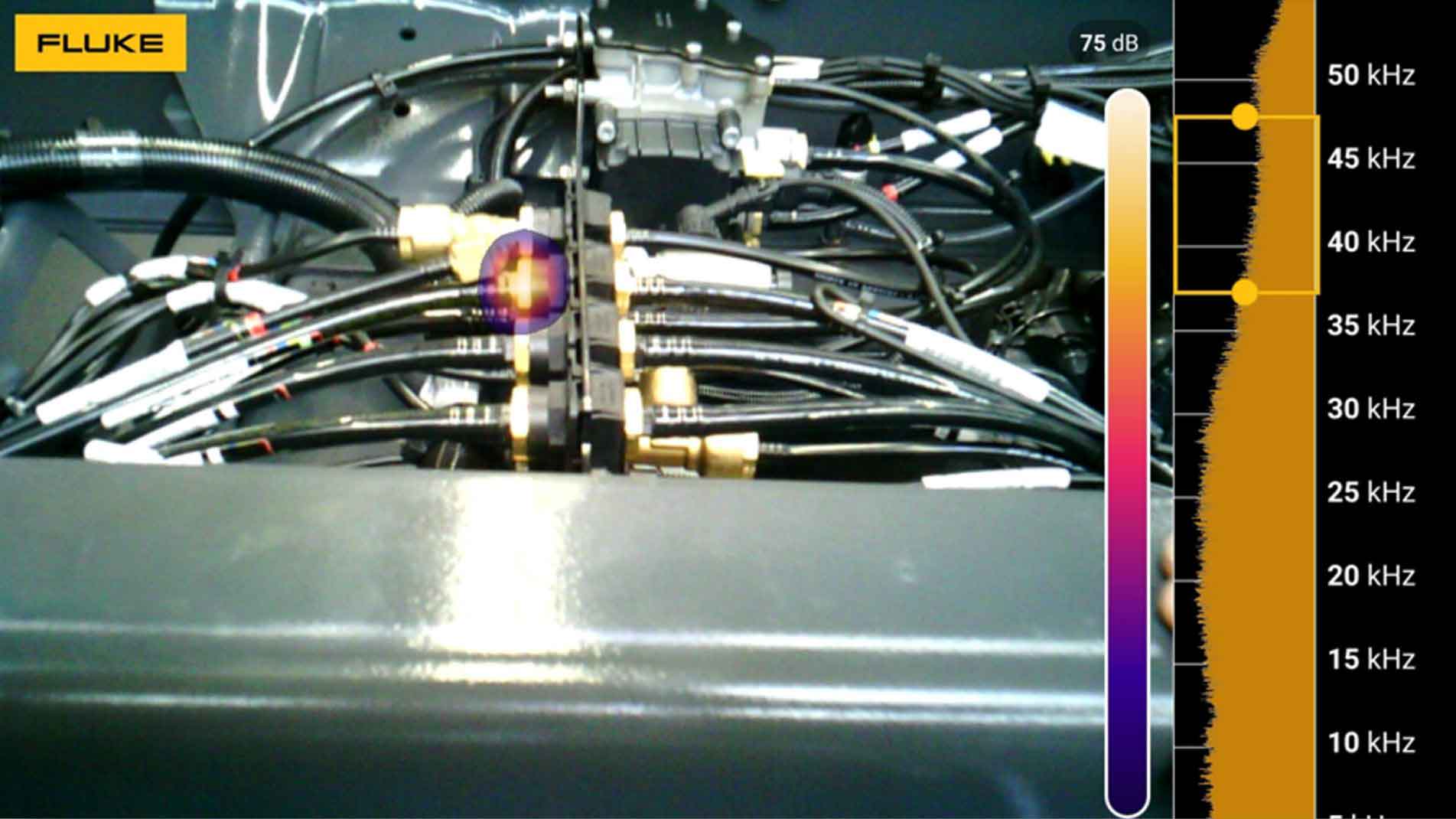

4. Valve Actuator Downtime

This is a valve actuator within a compressed gas system. This customer was unaware of this leak and had been compensating by increasing control air pressure. The unintended consequence was exceeding maximum pressure in other devices. This further reduced reliability of the process and caused downtime.

5. Air Handler Ducting Leaks in Gaskets and Fasteners

A paint booth ducting system. There are multiple leaks where there are bad gaskets and fasteners are loose or missing completely. These types of leaks have the potential to shut down the plant or contribute to environmental discharge. Maintenance was performed on this piece of equipment just the week before and the leaks went undetected.

6. Automotive Air Line Leaks Reduce Performance

These are pneumatic air lines in a semi-truck. Leaks in pneumatic systems are a quality defect that can impact the performance of onboard systems. Conventional methods of leak detection are extremely time consuming in these situations and can easily miss these types of leaks.

7. Product Reservoir Leaks Introduce Contamination

This product reservoir silos powder, or bread, which makes vinyl siding. A leak like this can impact batch integrity, such as contamination of the product due to infiltration of environmental particulates. Contaminates can also clog the silo and shut it down, leading to unplanned downtime. The Fluke ii900 identified a bad O-ring or over-torqued nut on the vessel door.

8. Dust Collection System Leaks Lead to Inefficient Performance

In this dust collection system, the ii900 spotted a leak in the pneumatics that operate the shaker in the system. This type of leak causes inefficient operation and could lead to added maintenance or else reduced performance or blocks.

9. HVAC Ductwork Leaks Introduce Failure Opportunities

Loss of pressure or vacuum in HVAC ducting can lead to contamination, faulty equipment, or environmental safety issues if not venting properly.

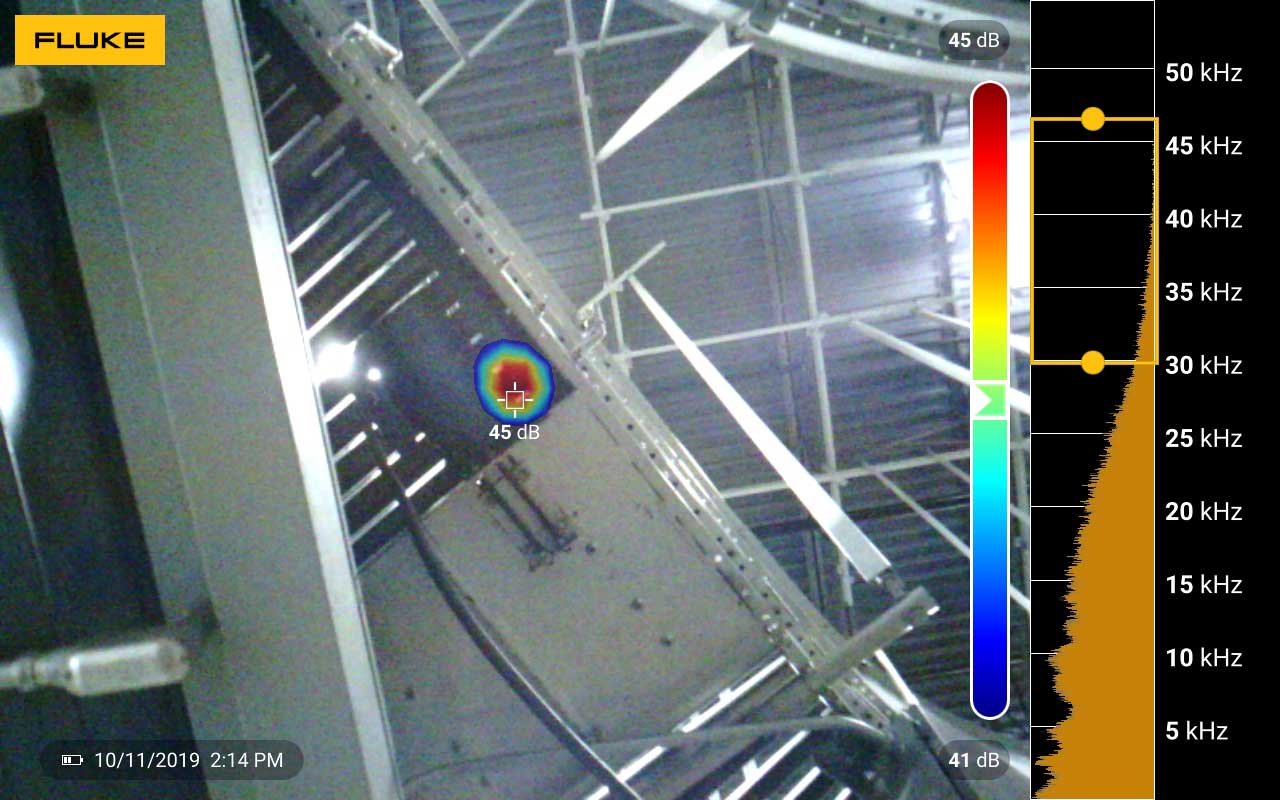

10. Overhead Roller Bearings Too High to Catch All Maintenance Needs

This is a conveyor system used to move boxes throughout the facility. Roller bearings require ongoing maintenance. In this example, the customer spent $4M USD on scaffolding to build access to the overhead areas for inspection and performance-required maintenance. They often built the scaffolding in the wrong place or inspected areas that did not require maintenance. The Fluke ii900 allowed for full-view inspection from the ground floor.

11. Control Air Regulator Not Venting Properly

12. Outdoor Holding Tank Leaking Expensive Gases

This is an outdoor argon holding tank. At this facility, the argon is piped from this storage tank into the facility and used in the production process. Argon is an expensive gas and when valves are leaking, that is money flowing directly out of the tank.

13. Robotics Leaks Impact Product Quality

This is a pick and place robot with pneumatic suction cups. If the suction or actuator is weak, picked parts could drop or not be placed in the right position impacted product quality. Often when suction issues are reported all components are replaced because it is difficult to isolate the problem. Rather than needing to check each cup independently, you can check for leaks with the Fluke ii900 during operation.

14. Steam System Leaks are Expensive

This steam system has leaks in the steam trap. Steam is expensive to produce. These types of systems are often inaccessible, making it difficult to identify issues.

Air or gas leaks can be difficult to identify, especially if you don’t know where to look. These examples show that leaks can be in many more places than the basic compressed air or gas systems, and the issues these leaks cause can be very expensive. Using the Fluke ii900 Sonic Industrial Imager, you can easily identify these and other types of air or gas leaks to keep your systems up and running efficiently.