Tachometer is a smart electronic device commonly used in measuring and displaying the rotation speed of a particular object. It plays an extremely important role in ensuring the performance and safety of machines. Therefore, Tachometer Calibration is an essential activity to support the production process. Nowadays, there are many types of tachometer in the market such as: contact tachometer, non-contact tachometer, … In this blog, let’s learn more about the Tachometer Calibration process at Techmaster company.

What is Tachometer?

Rotation speed is one of the most important factors to help evaluate the quality of the movement in mechanical equipment. It is necessary to check the rotational speed, and people use a tachometer to do that.

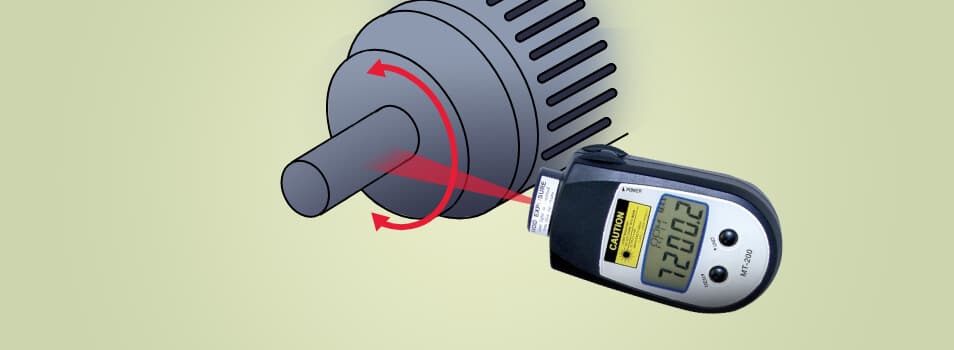

Tachometer can measure the rotational speed of engines and machines accurately. This device is designed in a handheld form to be convenient for measuring many types of engine equipment. It is widely used in the inspection and evaluation of machine quality. As a result, people can easily detect and fix electronic devices to ensure their accuracy.

Types of Tachometer

Nowadays, there are many types of tachometers on the market, divided into a variety of product categories. Tachometer is usually classified in the most common way based on contact with the load and measurement method:

- Contact Tachometer

- Non-contact Tachometer

- Frequency measuring

Learn more: The world’s popular tachometer – Top choices across the globe

Why Tachometer Calibration is important?

Tachometer is frequently used in manufacturing and technology, it is also required a high accuracy level. The inaccuracy may cause some problems affecting other manufacturing activities in the production process. Therefore, Businesses need to implement tachometer calibration to ensure the performance and safety of the related electronics. This activity can help employees using these devices detect some error from their device and fix it immediately.

Tachometer calibration process at Techmaster

Equipment for tachometer calibration

-

Frequency meter (Keysight 53220A)

-

Signal generator (Agilent 33250A)

-

Rubidium frequency standard (Pendulum 6689)

-

Contact type rotary speed calibrator (Tev RPMC-6000)

-

Auxiliary equipment: LED lights

-

Equipment to be calibrated (UUT): Contact and non-contact tachometers

Environmental conditions

-

Humidity: (40 ~ 70) %RH

-

Temperature: (20 ± 5) 0C

Process of Tachometer calibration

Calibration method: Compare the indication of the UUT with the standard frequency measurement system. Determine the UUT setting time accuracy.

Contact Tachometer

– Connect standard equipment system.

– Connect the UUT to the rotary shaft of the speed generator.

– Calibration in turn at points according to the procedure

– Export results.

Non-contact tachometer

– Connect standard equipment system.

– Put the UUT in the position suitable for the emitter

– Calibration in turn at points according to the procedure

– Export results.

We have already discovered the Tachometer Calibration and some related information about this device. To get further information about the Calibration service and Tachometer also, please connect us at Techmaster Vietnam.