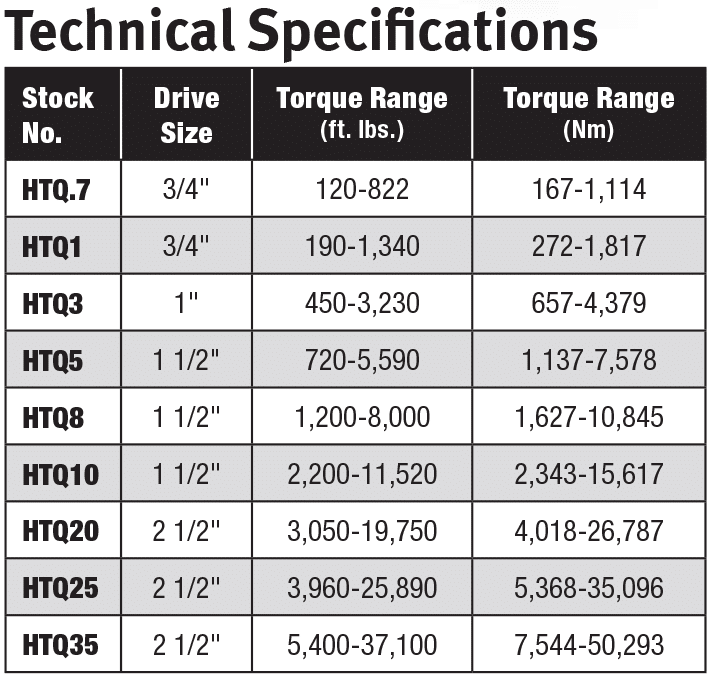

HTQ™ Series Hydraulic Torque Wrenches

ONE OF THE MOST FIELD PROVEN TOOLS IN THE WORLD MARKET TODAY, RECOMMENDED FOR ALL INDUSTRIAL TORQUE APPLICATIONS

- 1-way ratchet assures each nut is turned 24 ̊ to avoid a slow down due to bolt torsion as fasteners are getting tight

- Heavily corroded nuts create torsion in the bolt which can be overcome with a second stroke at full torque (one-way ratchet does not inadvertently let bolt torsion relax)

- On vertical applications, our tools find their proper reaction point without being held against it

- Ideal to use four tools to close flanges parallel

- Compact, ergonomic design for torque requirements up to 37,000 ft-lbs

- High strength metal square drive for performance and durability

- 360 degree rotatable tension absorbing reaction arm for a perfect fit on many jobs

- Uniswivel technology for free movement and positioning of tool and hoses

- Plus or minus 3% accuracy

- Limited Over-Stroke Mechanism

Dual Pawl Mechanism provides problem free operation and equal load ratchet mechanism - Corrosion free finish

Piston design prevents side load and the cylinder is maintenance free - Small operating radius…if a socket fits, the tool fits

- Ergonomic design

- An anti-backlash mechanism is the only way to get full torque on a corroded nut and prevent pre-stall or turning speed slow down. It is a must to operate multiple torque tools with a single hand and your only assurance to get preset torque on all fasteners no matter what!