Portable Liquid In Situ Particle Monitoring

Batch In Situ Particle Monitors (ISPMs) offer a rapid and cost effective requalification of wet process tools following chemical changes or filter replacement. In these applications, a particle counter is mounted on a cart and moved from one sample location to another. This mobile sampling approach maximizes the use of each particle counter, and provides particle contamination information in real-time for improved process tool utilization.

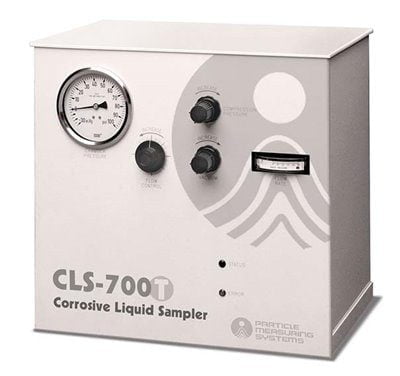

Unlike traditional surface scan test wafers, ISPMs characterize contamination in the individual baths being maintained. With an ISPM, samples can be taken directly from a process bath (figure 1) without special modification of the process tool, or lengthy down time. This article explains the use and benefits of portable liquid ISPMs especially their application within the semiconductor and like manufacturing industries.